View Poll Results: If I run in to valve to valve clearance problems do I

Keep sinking the valves

0

0%

Multiple Choice Poll. Voters: 4. You may not vote on this poll

Valve to valve clearance

#1

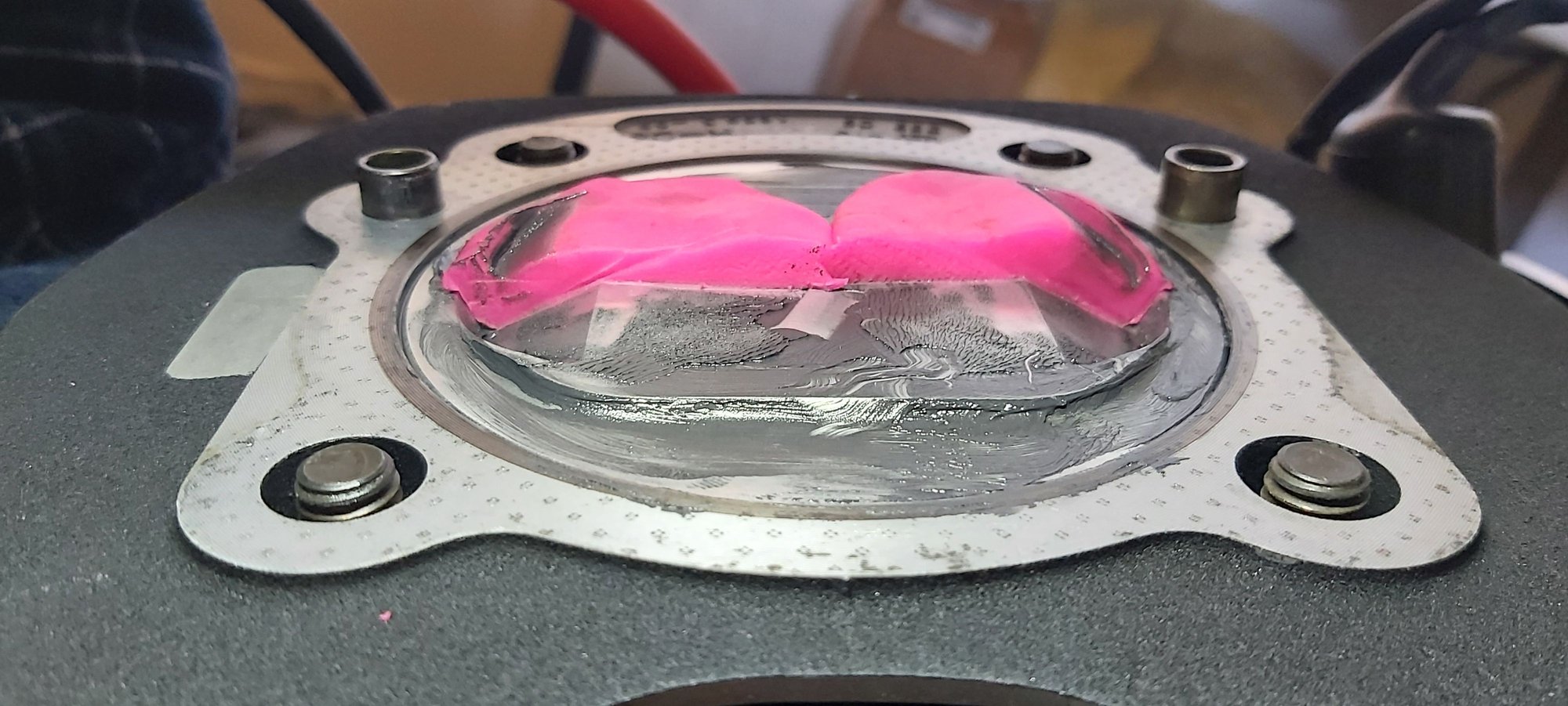

I'm in the middle of a 107" engine build on my 2010 Dyna Wide Glide and got in to some head modifications that are getting me in to some trouble now.....well my cams are also apart of my problem. My build is 107" with JE domed Racing pistons, S&S .640 cams, 1.675 ratio roller rockers, SE cam plate and pump, S&S adjustable pushrods, competition cams lifters and high lift springs. Heads are in the shop being ported and I chose 1.98 intake and 1.61 exhaust valves.

My question is if I don't have enough valve to valve clearance do we just keep sinking the valves? At what point is too far for sinking? Valve to piston clearance is good, just having problems with the valve to valve. We've already decked the head .053" to get compression back to 11.5:1. I really don't want to have to reseat and change valve size. People put bigger valves in than these though, sooo...

My question is if I don't have enough valve to valve clearance do we just keep sinking the valves? At what point is too far for sinking? Valve to piston clearance is good, just having problems with the valve to valve. We've already decked the head .053" to get compression back to 11.5:1. I really don't want to have to reseat and change valve size. People put bigger valves in than these though, sooo...

Last edited by Brads1971; 07-17-2021 at 10:32 AM.

#2

I don't have an answer but am sure there is a limit to how much you can sink the valves without running into loosing effective lift and possibly creating geometry issues but that's the opinion of a rank amateur pm on the subject. Did you use a Trock tool to check V to V clearance? What is the clearance? .060" is ideal but I have run at .040".

I assume you know that V to V clearance is not a function of total valve lift but lift at TDC? I think you have identified part of the problem being the cams you have chosen; maybe different cams with lower TDC lift? The S&S 640 seems a little OTT for a 107" build? With that much lift, why not stick with 1.625 OEM rocker arm ratio and see if that helps?

I have checked V to V clearance on several of my builds/rebuilds but have always had enough and never had to deal with the alternative so the subject is above my pay grade. However, I do like to reply in situations like this because there are a few members who are more knowledgeable on the subject than I am and when they weight in, I will learn something too.

I assume you know that V to V clearance is not a function of total valve lift but lift at TDC? I think you have identified part of the problem being the cams you have chosen; maybe different cams with lower TDC lift? The S&S 640 seems a little OTT for a 107" build? With that much lift, why not stick with 1.625 OEM rocker arm ratio and see if that helps?

I have checked V to V clearance on several of my builds/rebuilds but have always had enough and never had to deal with the alternative so the subject is above my pay grade. However, I do like to reply in situations like this because there are a few members who are more knowledgeable on the subject than I am and when they weight in, I will learn something too.

Last edited by djl; 07-17-2021 at 04:32 PM.

#3

I don't have an answer but am sure there is a limit to how much you can sink the valves without running into loosing effective lift and possibly creating geometry issues but that's the opinion of a rank amateur pm on the subject. Did you use a Trock tool to check V to V clearance? What is the clearance? .060" is ideal but I have run at .040".

I assume you know that V to V clearance is not a function of total valve lift but lift at TDC? I think you have identified part of the problem being the cams you have chosen; maybe different cams with lower TDC lift? The S&S 640 seems a little OTT for a 107" build? With that much lift, why not stick with 1.625 OEM rocker arm ratio and see if that helps?

I have checked V to V clearance on several of my builds/rebuilds but have always had enough and never had to deal with the alternative so the subject is above my pay grade. However, I do like to reply in situations like this because there are a few members who are more knowledgeable on the subject than I am and when they weight in, I will learn something too.

I assume you know that V to V clearance is not a function of total valve lift but lift at TDC? I think you have identified part of the problem being the cams you have chosen; maybe different cams with lower TDC lift? The S&S 640 seems a little OTT for a 107" build? With that much lift, why not stick with 1.625 OEM rocker arm ratio and see if that helps?

I have checked V to V clearance on several of my builds/rebuilds but have always had enough and never had to deal with the alternative so the subject is above my pay grade. However, I do like to reply in situations like this because there are a few members who are more knowledgeable on the subject than I am and when they weight in, I will learn something too.

640 lift is what I want. Building my hot rod. 🙂

I have checked clearance with oem rocker ratio and also with the roller rocker ratio and still need more. Besides, I can't use oem rockers with this much lift...well I can, but you know what everyone says.

I'm going back to the machine shop tonight to meet the machinist. We're going to go over everything done and see if we can take more off the stem tops. If we can then we will sink the vavle another .020 each more.

There's no shrouding of my valves. Each time the valves get sunk he blends it in. We loose compression but we get that back decking the head. Sink the valves then blend then check cc's and if the cc's aren't where I need it then we deck the head.

#5

#6

I set the valves at the specified lift then check with feeler guages. I tried using a snake camera with the head on to see if could see anything but cant get the right angle.

640 lift is what I want. Building my hot rod. 🙂

I have checked clearance with oem rocker ratio and also with the roller rocker ratio and still need more. Besides, I can't use oem rockers with this much lift...well I can, but you know what everyone says doesn't make it so.

I'm going back to the machine shop tonight to meet the machinist. We're going to go over everything done and see if we can take more off the stem tops. If we can then we will sink the vavle another .020 each more.

There's no shrouding of my valves. Each time the valves get sunk he blends it in. We loose compression but we get that back decking the head. Sink the valves then blend then check cc's and if the cc's aren't where I need it then we deck the head.

640 lift is what I want. Building my hot rod. 🙂

I have checked clearance with oem rocker ratio and also with the roller rocker ratio and still need more. Besides, I can't use oem rockers with this much lift...well I can, but you know what everyone says doesn't make it so.

I'm going back to the machine shop tonight to meet the machinist. We're going to go over everything done and see if we can take more off the stem tops. If we can then we will sink the vavle another .020 each more.

There's no shrouding of my valves. Each time the valves get sunk he blends it in. We loose compression but we get that back decking the head. Sink the valves then blend then check cc's and if the cc's aren't where I need it then we deck the head.

I see that you have duplicated this post in the engine section; suggest you pick one and stick with it for the best feedback. There are a couple of pretty knowledgeable members replying on the other thread. Good luck, I will be following to see what you do and hope you will come back and post the final details of the build and the resluting dyno sheet.

Last edited by djl; 07-18-2021 at 12:04 PM.

#7

I have run .610" lift cams on OEM rockers in an all bore 107" motor at 124TQ/110HP with no issues disregarding what everyone says but at .640", that would probably be an issue; not that you would run them but just to point out that "what everyone" says.

I see that you have duplicated this post in the engine section; suggest you pick one and stick with it for the best feedback. There are a couple of pretty knowledgeable members replying on the other thread. Good luck, I will be following to see what you do and hope you will come back and post the final details of the build and the resluting dyno sheet.

I see that you have duplicated this post in the engine section; suggest you pick one and stick with it for the best feedback. There are a couple of pretty knowledgeable members replying on the other thread. Good luck, I will be following to see what you do and hope you will come back and post the final details of the build and the resluting dyno sheet.

thanks I'll go look at that post. 🙂

Thread

Thread Starter

Forum

Replies

Last Post