Rear Axle Bearing Retainer Plates

#1

After replacing the worn heim joints there was still play when we rocked the rear wheels.

It was less than before replacing the heim joints, but there was still a significant amount of movement and audible clicking/clanking.

We thought it must be the rear axle bearings going bad. So we removed the rear axle, and boy what a surprise!

The bearing was not bad, no play in it, and no grease leaking out of the sealed bearing.

What we did discover is that the entire bearing was rocking back and forth in the axle housing.

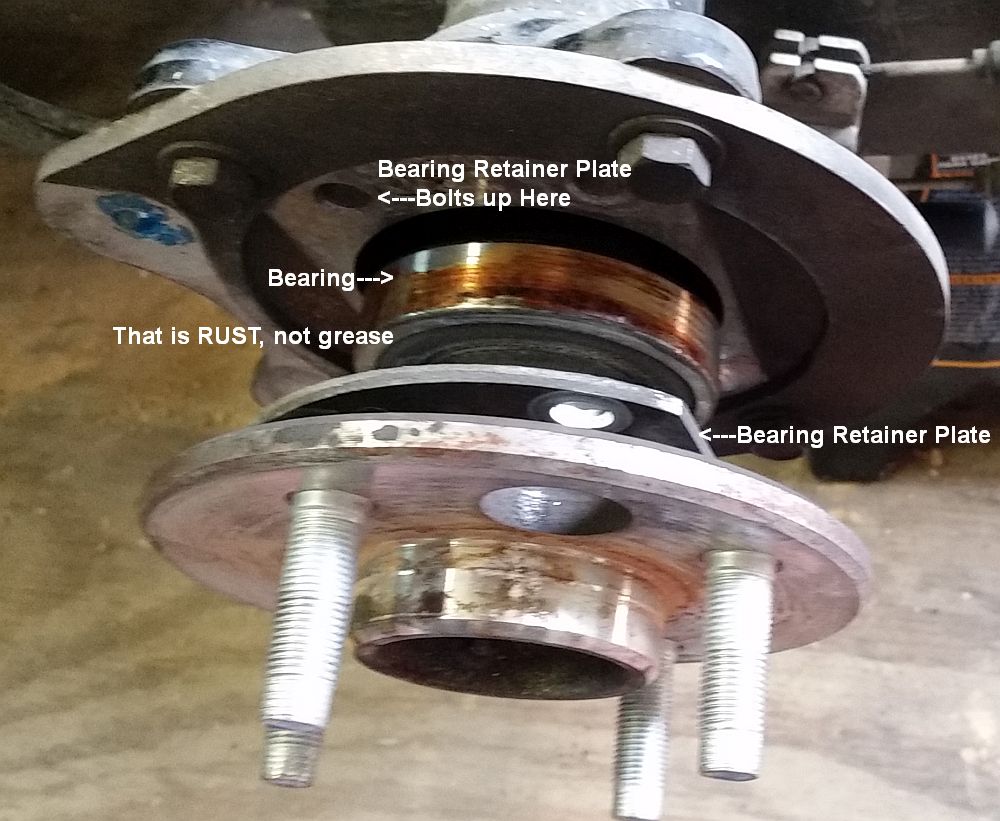

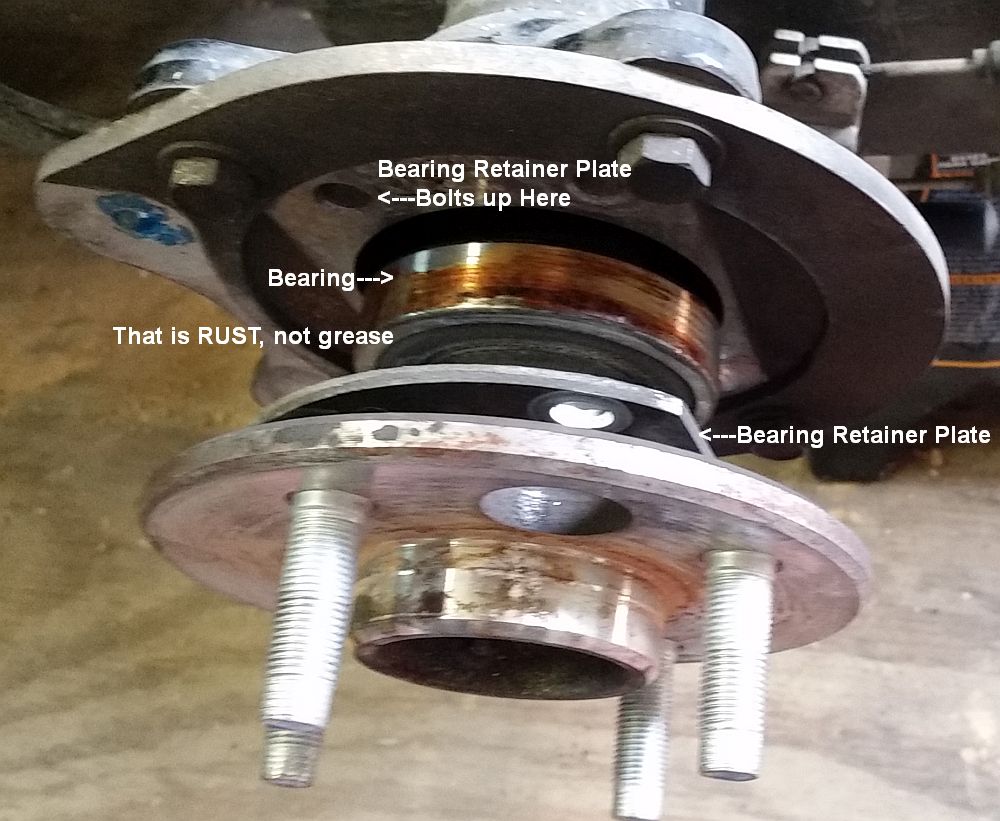

The bearing retainer plate is supposed to hold the bearing tight in the housing. It was not. Instead, the plate was allowing the bearing to rock in the housing. Below is a photo of what we saw right off the bat...

...witness marks on the plate where the bearing was banging up against it.

Here's a better photo of both plates, where the witness marks are clearly visible.

What may be even more disconcerting is how much the outer surface of the bearings were banged up from all the movement in the axle housing.

What is supposed to happen is that the bearing fits snugly in the axle housing, and then the bearing retainer plate is supposed to tighten up against the outer bearing surface and hold the bearing immobile in the housing.

Instead, because of loose HD tolerances, AND because the bearing retainer plate is a stamped material, AND too thin, it loses (or never had) it's completely flat surface. The result is that there is space between the outer bearing surface and the retainer plate.

This allows the bearing to move inside the axle housing, resulting in:

1. Banging up the bearing

2. Banging up/wearing the inner diameter of the axle housing

3. Back & forth Tire/wheel movement, which results in clicking, clanking and #4 below

4. Since the wheel end of the axle has rocking movement, that means the far end of the axle (which sits in the differential) has even more up and down movement. This results in worn splines, or worse!

Photo of axle housing worn because of bearing movement-

Photo of worn splines...

...these are not horrible, because I caught it early enough.

The last thing we saw that we did not like, although it is not a potential for catastrophic failure like the above, is that there is not a good seal to keep water out of the axle housing.

As seen in this photo, water can just sit in the axle housing and start rusting-

After discovering the above, I went out and spent some time grabbing some rear tires of different HD Trikes and seeing if there was rocking movement in them.

2 brand new ones has no movement

1 with around 5K miles had no movement

1 with around 3K miles has just a little bit of movement

3 others, ranging between 12K and 35K miles all had movement similar to mine (which has 50K miles).

Since I am leaving on a long trip shortly, I did not want to just put it back together and hope I did not have a problem while out on the road.

I also did not want to just replace the bearing retainer plates with some new ones...obviously it would happen again, and probably faster, since the axle housing is a bit beat up/misshapened.

The next post outlines what we did-

It was less than before replacing the heim joints, but there was still a significant amount of movement and audible clicking/clanking.

We thought it must be the rear axle bearings going bad. So we removed the rear axle, and boy what a surprise!

The bearing was not bad, no play in it, and no grease leaking out of the sealed bearing.

What we did discover is that the entire bearing was rocking back and forth in the axle housing.

The bearing retainer plate is supposed to hold the bearing tight in the housing. It was not. Instead, the plate was allowing the bearing to rock in the housing. Below is a photo of what we saw right off the bat...

...witness marks on the plate where the bearing was banging up against it.

Here's a better photo of both plates, where the witness marks are clearly visible.

What may be even more disconcerting is how much the outer surface of the bearings were banged up from all the movement in the axle housing.

What is supposed to happen is that the bearing fits snugly in the axle housing, and then the bearing retainer plate is supposed to tighten up against the outer bearing surface and hold the bearing immobile in the housing.

Instead, because of loose HD tolerances, AND because the bearing retainer plate is a stamped material, AND too thin, it loses (or never had) it's completely flat surface. The result is that there is space between the outer bearing surface and the retainer plate.

This allows the bearing to move inside the axle housing, resulting in:

1. Banging up the bearing

2. Banging up/wearing the inner diameter of the axle housing

3. Back & forth Tire/wheel movement, which results in clicking, clanking and #4 below

4. Since the wheel end of the axle has rocking movement, that means the far end of the axle (which sits in the differential) has even more up and down movement. This results in worn splines, or worse!

Photo of axle housing worn because of bearing movement-

Photo of worn splines...

...these are not horrible, because I caught it early enough.

The last thing we saw that we did not like, although it is not a potential for catastrophic failure like the above, is that there is not a good seal to keep water out of the axle housing.

As seen in this photo, water can just sit in the axle housing and start rusting-

After discovering the above, I went out and spent some time grabbing some rear tires of different HD Trikes and seeing if there was rocking movement in them.

2 brand new ones has no movement

1 with around 5K miles had no movement

1 with around 3K miles has just a little bit of movement

3 others, ranging between 12K and 35K miles all had movement similar to mine (which has 50K miles).

Since I am leaving on a long trip shortly, I did not want to just put it back together and hope I did not have a problem while out on the road.

I also did not want to just replace the bearing retainer plates with some new ones...obviously it would happen again, and probably faster, since the axle housing is a bit beat up/misshapened.

The next post outlines what we did-

#2

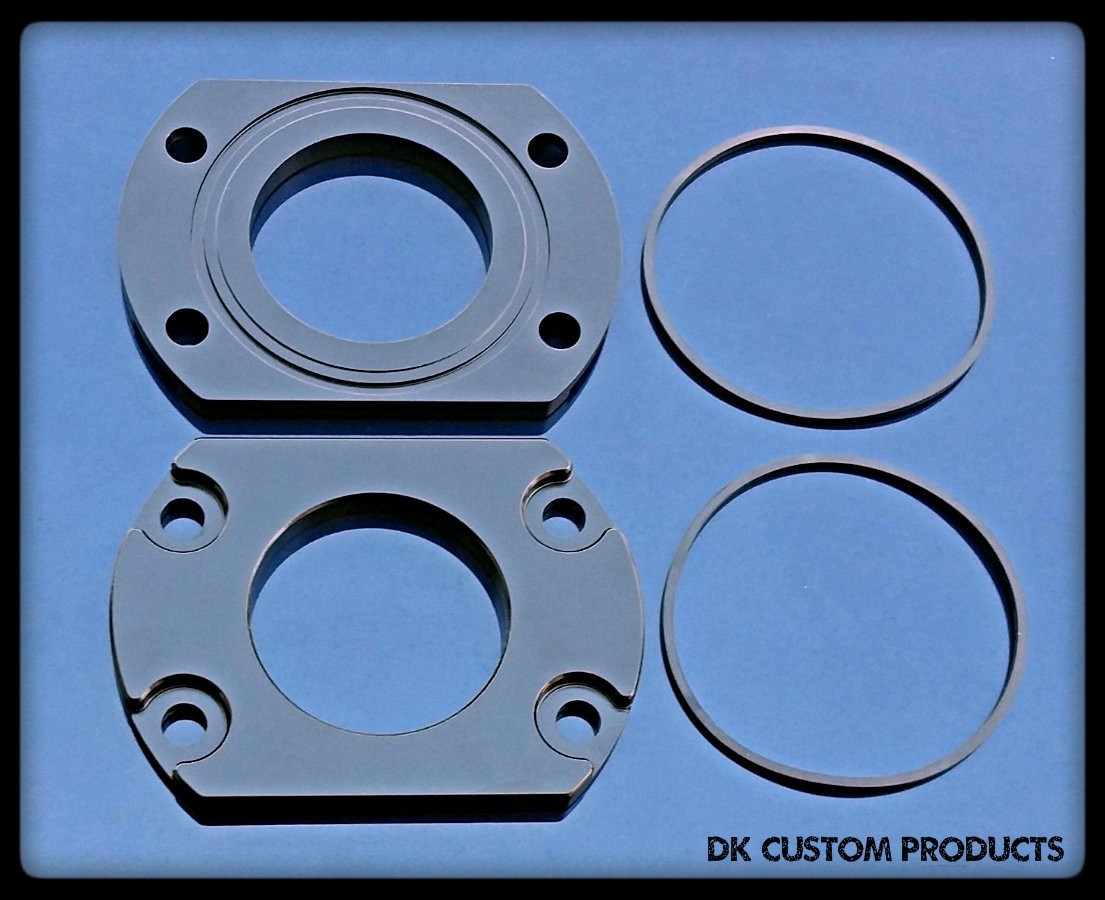

After being thoroughly surprised, dismayed and generally wondering what I was going to do, with our trip right around the corner, we decided to make our own bearing retainer plates....Ones that would work, and not have a problem down the road.

First thing we did was pull the snap rings, then press off the the axle retainers and bearings. That gave us access to the defective retainer plates.

Devin then designed a new plate. 2.5 x's as thick. It is cut from 1018 American Steel...not stamped.

It also has a 2/100" shoulder that butts up against the bearing. This makes sure that there is NO rocking or movement of the bearing in the axle housing, even if that surface it bolts to is not completely flat (accommodating poor tolerances).

It also has a place for an o-ring, so there is no chance of water getting in there and sitting.

Ready to install with new bearing and plate with an o-ring.

Installation went easy-

All done!

I now have several hundred miles with this new setup. It is rock solid with no clicking, clacking or wandering.

Most importantly, I'm no longer concerned about something tearing up while on our trip.

First thing we did was pull the snap rings, then press off the the axle retainers and bearings. That gave us access to the defective retainer plates.

Devin then designed a new plate. 2.5 x's as thick. It is cut from 1018 American Steel...not stamped.

It also has a 2/100" shoulder that butts up against the bearing. This makes sure that there is NO rocking or movement of the bearing in the axle housing, even if that surface it bolts to is not completely flat (accommodating poor tolerances).

It also has a place for an o-ring, so there is no chance of water getting in there and sitting.

Ready to install with new bearing and plate with an o-ring.

Installation went easy-

All done!

I now have several hundred miles with this new setup. It is rock solid with no clicking, clacking or wandering.

Most importantly, I'm no longer concerned about something tearing up while on our trip.

The following 2 users liked this post by DK Custom:

Cagmo (05-03-2018),

talkingrock (05-18-2018)

#5

After my new RoadKing returns from the body hospital (thanks to a distracted driver) I am going to attack the wandering issue on my TriGlide (probably June). I posted this before...bottom line...under warranty dealer can not reproduce. So, now Iím out of warranty and itís worse...especially when loaded. So, hereís my plan:

1) Replace front tire that is nearly worn out. Also replace front wheel bearings at the same time.

2) Replace rear tires that have 40K miles and are 6 years old

3) Replace heim joints, that I know have play...but dealer said in spec.

4) Check rear wheel wiggle...per your above.

Hopefully the above resolves the issue...otherwise...I donít know.

1) Replace front tire that is nearly worn out. Also replace front wheel bearings at the same time.

2) Replace rear tires that have 40K miles and are 6 years old

3) Replace heim joints, that I know have play...but dealer said in spec.

4) Check rear wheel wiggle...per your above.

If it wiggles side to side, go after the bearings and bearing plates, but that might be more than I want to do myself..

5) If the above doesnít address the issue...try tightening up the front steering head bearing. IMHO...the swing thing is BS, on a loaded up fairing. Hopefully the above resolves the issue...otherwise...I donít know.

#10

Yes, by Monday afternoon there will be a step-by-step installation guide on the website.

It is really quite easy.

Remove the tires

Remove brake caliper (two bolts)

Remove 4 nuts holding bearing retainer plate

Pull entire axle out (it just slides out)

Press bearing off axle (or carry to a shop and have them press the bearing off the axle)

Drop Heavy Duty Bearing Retainer on to axle

Press old (or new) bearing back on axle

Slide axle back into trike

Tighten 4 nuts down, holding retainer

Bolt caliper back on

Put wheel back on

No special tools are needed, other than pressing bearing off and on.

Two sockets and some thread-locker.