Slack in Rear Drive Belt

#12

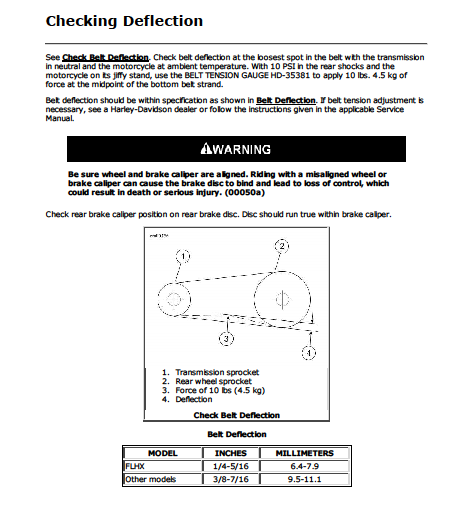

I adjusted the weld nut on the left side to create the desired tension on the belt when I got home tonight. However, when I tightened the cone nut on the right side to 95 ftlbs according to the manual, the wheel was completely locked. Wouldn't move at all. I loosened everything back up and tried again but got the same results. Page 1-31 in the manual gives the torque specs (95-105 ftlbs). I also used two different torque wrenches in case one was off. Same results. If I leave the cone nut on the right loose enough to rotate the wheel, then the weld nut on the left side will be too loose and the belt will become slack. The e-clip (retaining ring) will keep the cone nut from coming off the axle if it is loose but it won't maintain the desired tension on the belt. What am I missing here? This is the last thing holding me up from riding the bike. Hope someone can help. Thanks.

#13

#14

Your having a hard time getting your head around belt deflection procedure and rear wheel installation and rear brake etc,,,, These are important areas as you would appreciate ..... I would find someone close by, to you to go through the whole exercise with you, (or go straight to a workshop ).. .....

Giving advice may get you into all sorts of trouble .....But , with your wheel locking up when tightning the axle ,, Looks like item 10 has moved out of position , causing the caliper to moving out of position, ie locking up wheel ...

Please come back when you get it all sorted,, so we know your not lying on the side of a road somewhere .....

Giving advice may get you into all sorts of trouble .....But , with your wheel locking up when tightning the axle ,, Looks like item 10 has moved out of position , causing the caliper to moving out of position, ie locking up wheel ...

Please come back when you get it all sorted,, so we know your not lying on the side of a road somewhere .....

Last edited by markwolula; 02-09-2017 at 05:32 AM.

#15

I adjusted the weld nut on the left side to create the desired tension on the belt when I got home tonight. However, when I tightened the cone nut on the right side to 95 ftlbs according to the manual, the wheel was completely locked. Wouldn't move at all. I loosened everything back up and tried again but got the same results. Page 1-31 in the manual gives the torque specs (95-105 ftlbs). I also used two different torque wrenches in case one was off. Same results. If I leave the cone nut on the right loose enough to rotate the wheel, then the weld nut on the left side will be too loose and the belt will become slack. The e-clip (retaining ring) will keep the cone nut from coming off the axle if it is loose but it won't maintain the desired tension on the belt. What am I missing here? This is the last thing holding me up from riding the bike. Hope someone can help. Thanks.

#16

The caliper mount bracket (#10) will only mount one way so I don't believe that is the problem. However, I intend to look at it again tonight and verify that all the spacers and other components are in the same order as the diagram. Everything lines up and spins perfectly when the axle nut is slightly tight but it binds quickly when I tighten the nut a little more.

#17

Finally found the problem. The "click" on my torque wrench sounds so light that I never heard it the other night. I was tightening the cone nut way too tight while listening for a click that had already sounded. When I heard that tiny click tonight, I knew that was it. Sure enough, the wheel rotates good and the belt retains its tension. Saturday is supposed to be 70 degrees and nothing but sun here in middle GA. Perfect day to get back on the road after I test everything in my driveway. I spent the winter repainting it, new tires and wheels, new exhaust, new tuner and dynotune, new braided brake lines and front fender. It looks like a completely different bike now. Bring on the sunshine!

#20