Cam tensioners and Questions

#12

With some relatively specialized equipment. Involves using a dial or test indicator and rotating the engine to see how much the crankshaft is running out from zero. .003 inch or less (less is better) is pretty much required to use gear drive cams. Your '06 would be a candidate to at least have it checked to see. That is if you are willing to spend the money. Much depends on what your plans are for the engine.

#16

#17

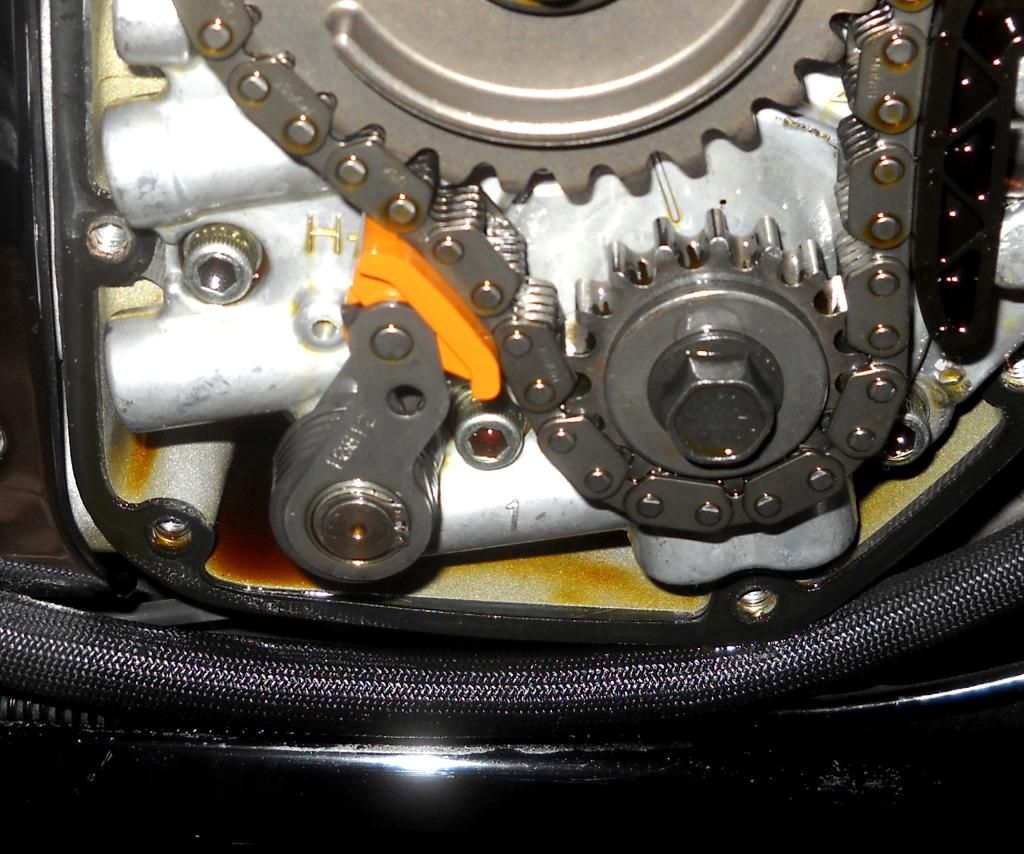

I may be stupid but when I took mine down I saw no way whatsoever to view the wearing surface of the inner tensioner shoe... mirrors, lights, you name it. You cannot tell if it is starting to pit and thus self destruct unless you pull the cam support plate and pull the cams or use a special tool to open the tensioner without removing the cams. You must see the >surface< of the shoe.

In my opinion there are three things that will help this problem... 1. buy adjustable push rods and cut the originals, support the lifters with magnets, and pull the cam support plate replacing the tensioners every 25-30k miles. 2. Use synthetic oil. 3. Keep your engine temperature as low as you can through non-EPA compliant AFR fuel mixture ratios and/or an oil cooler.

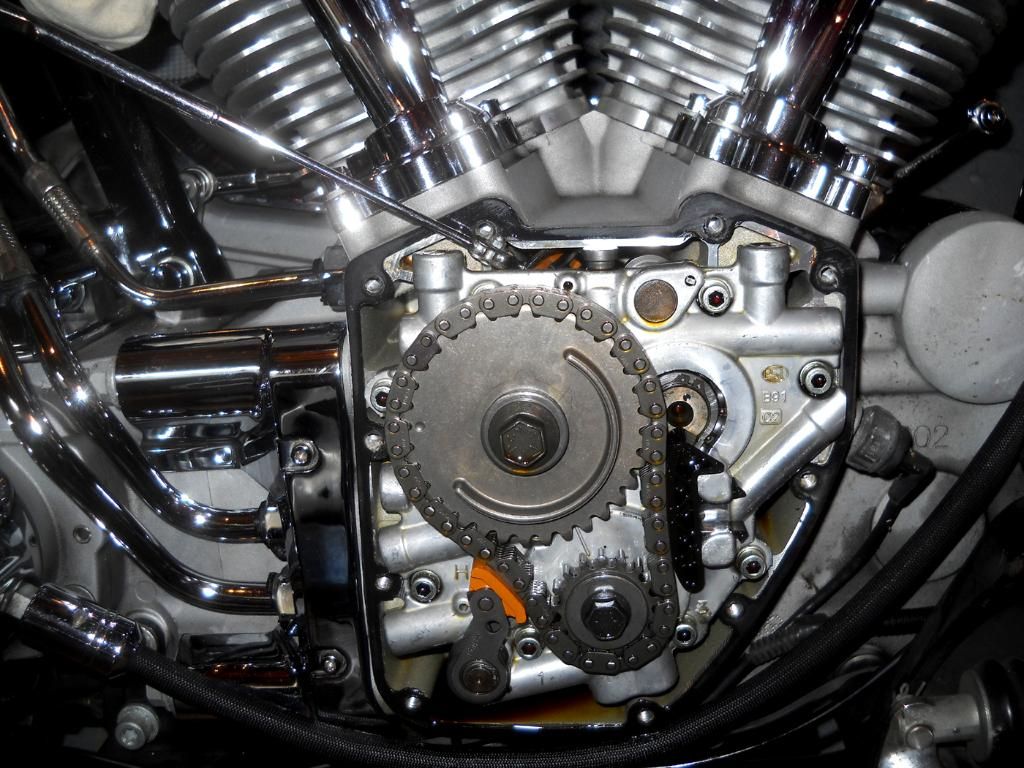

You can also change out your cams and cam support plate to one that uses roller chains on BOTH sides and use 2. and 3. above.

C#

In my opinion there are three things that will help this problem... 1. buy adjustable push rods and cut the originals, support the lifters with magnets, and pull the cam support plate replacing the tensioners every 25-30k miles. 2. Use synthetic oil. 3. Keep your engine temperature as low as you can through non-EPA compliant AFR fuel mixture ratios and/or an oil cooler.

You can also change out your cams and cam support plate to one that uses roller chains on BOTH sides and use 2. and 3. above.

C#

Thread

Thread Starter

Forum

Replies

Last Post