2001 Softail Twin Cam 88 95" Upgrade

#22

One other thought about the valve job: Manufacturers of larger valves offer valves with improved shape over the stock valves. The different shape also allows for improved flow at lower lifts compared to the shape of the stock valves. Unfortunately, I do not have a picture to illustrate this. I appreciate the conflict between your logical and gearhead personalities. I only suggest this, whatever you decide: do the head work (if any) when you do your build. It will be cheaper (unless you do all the work yourself), and result in less down time. Why spend more money, or remove your heads more times than needed? There may even be valves at stock sizes with the improved shape. Again, good luck, whatever you choose, and here's hoping you enjoy the results, and also many tens of thousands of miles of happy and safe riding!

#23

But saving up for something nice is really rewarding.

Whether I do any mods or not, I will most likely still have the bike tuned in the spring. From what i read, that is the best money spent. I have a PCIII on it now, I don't know what would have been changed when the cams were put in, so i Dyno Tune by a professional should be good, then I know what it made before I do any mods later

One other thought about the valve job: Manufacturers of larger valves offer valves with improved shape over the stock valves. The different shape also allows for improved flow at lower lifts compared to the shape of the stock valves. Unfortunately, I do not have a picture to illustrate this. I appreciate the conflict between your logical and gearhead personalities. I only suggest this, whatever you decide: do the head work (if any) when you do your build. It will be cheaper (unless you do all the work yourself), and result in less down time. Why spend more money, or remove your heads more times than needed? There may even be valves at stock sizes with the improved shape. Again, good luck, whatever you choose, and here's hoping you enjoy the results, and also many tens of thousands of miles of happy and safe riding!

Thanks guys

Can't wait for spring!

#24

Dan33klein,

I just read the whole thread and lots of good advice has been posted but as a previous poster had pointed out, you need to figure out how much you can afford to spend on upgrades, now or in the spring and whether or not you plan to do the work yourself, which I would encourage you to do.

There are several ways to skin the "build" cat that have the same results but some ways cost more than others and there, as you would expect, trade offs.

Some general guidelines for you to consider:

1. Inreasing displacement to 95" or 98" is the cheapest power you can buy. Additionally, if you are going to bore, why not bore to 98"; the extra displacement is free. If you were only going to do one thing, increasing displacement is the one thing you should do.

2. The 510 cams you have are decent but they need more compression to maximize their performance. If you were to increase displacement only, sinc you have the heads off, it would only make sense to deck them to set compression in the sweet spot for those cams, have a competition (SERDI) valve job done and use the OEM heads. Cheap but effective.

3. Having said what I did in #2, you need to know that the TC88 heads are a real bottleneck to performance. If your funds were limited, you could "get by" with #2 but if funds were available, a set of "06 or later heads cleaned up, decked for compression with a competition valve job would be a real improvement over #2 but, yeah, it would cost more money.

4. The next step up with the heads would be to have the '06 or later set of heads ported; yeah; mo money! I would not waste the money to port your early heads as they have the .310" diameter valve stem vice the .275" valve stem in the '05 and later heads as well as the beehive springs that will accomodate higher cam lifts in lieu of the early straight wound springs. So, there are three "steps" in the approach to improving your cylinder heads that have cost impact.

5. Personally, I would recommend against the domed pistons and stick with flat tops and mill the heads for compression; just have had better luck with flat tops.

6. Your pipes suck; sorry but that's a fact. I know, pipes are very subjective and many prefer form over function buta solid 2:1 like a Python 3, V&H Propipe, Thunderheader, etc. will deliver more torque.

As far as cam chest and oil pump upgrades, there are many ways to approach that but at a minimum you should replace the OEM tensioner shoes with the new CYCO shoes and insntall the Baisley LMR-002 spring in the early pump to provide a little more low rpm oil pressure. The Harley oil system is a volume based system, not pressure based. Once again, you are faced with options which all have cost impact, i.e., gear drives?, SE Hybrid cam plate kit??, '07 cam plate and conversion cams?? (probably don't want that becaue you already have cams).

So, after beating around the bush, it really is important to answer the two questions; how much can you afford to spend and will you be doing the work yourself. JMHO.

I just read the whole thread and lots of good advice has been posted but as a previous poster had pointed out, you need to figure out how much you can afford to spend on upgrades, now or in the spring and whether or not you plan to do the work yourself, which I would encourage you to do.

There are several ways to skin the "build" cat that have the same results but some ways cost more than others and there, as you would expect, trade offs.

Some general guidelines for you to consider:

1. Inreasing displacement to 95" or 98" is the cheapest power you can buy. Additionally, if you are going to bore, why not bore to 98"; the extra displacement is free. If you were only going to do one thing, increasing displacement is the one thing you should do.

2. The 510 cams you have are decent but they need more compression to maximize their performance. If you were to increase displacement only, sinc you have the heads off, it would only make sense to deck them to set compression in the sweet spot for those cams, have a competition (SERDI) valve job done and use the OEM heads. Cheap but effective.

3. Having said what I did in #2, you need to know that the TC88 heads are a real bottleneck to performance. If your funds were limited, you could "get by" with #2 but if funds were available, a set of "06 or later heads cleaned up, decked for compression with a competition valve job would be a real improvement over #2 but, yeah, it would cost more money.

4. The next step up with the heads would be to have the '06 or later set of heads ported; yeah; mo money! I would not waste the money to port your early heads as they have the .310" diameter valve stem vice the .275" valve stem in the '05 and later heads as well as the beehive springs that will accomodate higher cam lifts in lieu of the early straight wound springs. So, there are three "steps" in the approach to improving your cylinder heads that have cost impact.

5. Personally, I would recommend against the domed pistons and stick with flat tops and mill the heads for compression; just have had better luck with flat tops.

6. Your pipes suck; sorry but that's a fact. I know, pipes are very subjective and many prefer form over function buta solid 2:1 like a Python 3, V&H Propipe, Thunderheader, etc. will deliver more torque.

As far as cam chest and oil pump upgrades, there are many ways to approach that but at a minimum you should replace the OEM tensioner shoes with the new CYCO shoes and insntall the Baisley LMR-002 spring in the early pump to provide a little more low rpm oil pressure. The Harley oil system is a volume based system, not pressure based. Once again, you are faced with options which all have cost impact, i.e., gear drives?, SE Hybrid cam plate kit??, '07 cam plate and conversion cams?? (probably don't want that becaue you already have cams).

So, after beating around the bush, it really is important to answer the two questions; how much can you afford to spend and will you be doing the work yourself. JMHO.

#25

Dan33klein,

I just read the whole thread and lots of good advice has been posted but as a previous poster had pointed out, you need to figure out how much you can afford to spend on upgrades, now or in the spring and whether or not you plan to do the work yourself, which I would encourage you to do.

There are several ways to skin the "build" cat that have the same results but some ways cost more than others and there, as you would expect, trade offs.

Some general guidelines for you to consider:

1. Inreasing displacement to 95" or 98" is the cheapest power you can buy. Additionally, if you are going to bore, why not bore to 98"; the extra displacement is free. If you were only going to do one thing, increasing displacement is the one thing you should do.

I just seen that 95" seems to be really common.

Also i assumed going to 98" with stock cylinders might make the walls thin.

Correct me if im wrong

2. The 510 cams you have are decent but they need more compression to maximize their performance. If you were to increase displacement only, sinc you have the heads off, it would only make sense to deck them to set compression in the sweet spot for those cams, have a competition (SERDI) valve job done and use the OEM heads. Cheap but effective.

According to S&S the 510 cams like right around 9.8:1

3. Having said what I did in #2, you need to know that the TC88 heads are a real bottleneck to performance. If your funds were limited, you could "get by" with #2 but if funds were available, a set of "06 or later heads cleaned up, decked for compression with a competition valve job would be a real improvement over #2 but, yeah, it would cost more money.

4. The next step up with the heads would be to have the '06 or later set of heads ported; yeah; mo money! I would not waste the money to port your early heads as they have the .310" diameter valve stem vice the .275" valve stem in the '05 and later heads as well as the beehive springs that will accomodate higher cam lifts in lieu of the early straight wound springs. So, there are three "steps" in the approach to improving your cylinder heads that have cost impact.

I am going to keep my eye out for a set of 06 and later heads, i can pry pick up a set for the same price to port my stock heads. and I will still have a better head.

5. Personally, I would recommend against the domed pistons and stick with flat tops and mill the heads for compression; just have had better luck with flat tops.

The only reason i picked the domed pistons is because big boyz cycles calculator said with the dome pistons/.030" HG, 510 cams and stock heads it would used 9.82 correct compression.

If that tops and milling is better, i would go that route

6. Your pipes suck; sorry but that's a fact. I know, pipes are very subjective and many prefer form over function buta solid 2:1 like a Python 3, V&H Propipe, Thunderheader, etc. will deliver more torque.

I've heard these pips are not really that great, I love the look of them and would not want drop cash on new ones, as long as i can get a good tune with them im not worried about a few HP

As far as cam chest and oil pump upgrades, there are many ways to approach that but at a minimum you should replace the OEM tensioner shoes with the new CYCO shoes and insntall the Baisley LMR-002 spring in the early pump to provide a little more low rpm oil pressure. The Harley oil system is a volume based system, not pressure based. Once again, you are faced with options which all have cost impact, i.e., gear drives?, SE Hybrid cam plate kit??, '07 cam plate and conversion cams?? (probably don't want that becaue you already have cams).

Yes, I really don't want to get that deep in modifying the motor, I won't be buying new cams as i already have them.

Can you provide more info and where to purchase the new shoes?

Any info on changing the spring?

So, after beating around the bush, it really is important to answer the two questions; how much can you afford to spend and will you be doing the work yourself. JMHO.

I just read the whole thread and lots of good advice has been posted but as a previous poster had pointed out, you need to figure out how much you can afford to spend on upgrades, now or in the spring and whether or not you plan to do the work yourself, which I would encourage you to do.

There are several ways to skin the "build" cat that have the same results but some ways cost more than others and there, as you would expect, trade offs.

Some general guidelines for you to consider:

1. Inreasing displacement to 95" or 98" is the cheapest power you can buy. Additionally, if you are going to bore, why not bore to 98"; the extra displacement is free. If you were only going to do one thing, increasing displacement is the one thing you should do.

I just seen that 95" seems to be really common.

Also i assumed going to 98" with stock cylinders might make the walls thin.

Correct me if im wrong

2. The 510 cams you have are decent but they need more compression to maximize their performance. If you were to increase displacement only, sinc you have the heads off, it would only make sense to deck them to set compression in the sweet spot for those cams, have a competition (SERDI) valve job done and use the OEM heads. Cheap but effective.

According to S&S the 510 cams like right around 9.8:1

3. Having said what I did in #2, you need to know that the TC88 heads are a real bottleneck to performance. If your funds were limited, you could "get by" with #2 but if funds were available, a set of "06 or later heads cleaned up, decked for compression with a competition valve job would be a real improvement over #2 but, yeah, it would cost more money.

4. The next step up with the heads would be to have the '06 or later set of heads ported; yeah; mo money! I would not waste the money to port your early heads as they have the .310" diameter valve stem vice the .275" valve stem in the '05 and later heads as well as the beehive springs that will accomodate higher cam lifts in lieu of the early straight wound springs. So, there are three "steps" in the approach to improving your cylinder heads that have cost impact.

I am going to keep my eye out for a set of 06 and later heads, i can pry pick up a set for the same price to port my stock heads. and I will still have a better head.

5. Personally, I would recommend against the domed pistons and stick with flat tops and mill the heads for compression; just have had better luck with flat tops.

The only reason i picked the domed pistons is because big boyz cycles calculator said with the dome pistons/.030" HG, 510 cams and stock heads it would used 9.82 correct compression.

If that tops and milling is better, i would go that route

6. Your pipes suck; sorry but that's a fact. I know, pipes are very subjective and many prefer form over function buta solid 2:1 like a Python 3, V&H Propipe, Thunderheader, etc. will deliver more torque.

I've heard these pips are not really that great, I love the look of them and would not want drop cash on new ones, as long as i can get a good tune with them im not worried about a few HP

As far as cam chest and oil pump upgrades, there are many ways to approach that but at a minimum you should replace the OEM tensioner shoes with the new CYCO shoes and insntall the Baisley LMR-002 spring in the early pump to provide a little more low rpm oil pressure. The Harley oil system is a volume based system, not pressure based. Once again, you are faced with options which all have cost impact, i.e., gear drives?, SE Hybrid cam plate kit??, '07 cam plate and conversion cams?? (probably don't want that becaue you already have cams).

Yes, I really don't want to get that deep in modifying the motor, I won't be buying new cams as i already have them.

Can you provide more info and where to purchase the new shoes?

Any info on changing the spring?

So, after beating around the bush, it really is important to answer the two questions; how much can you afford to spend and will you be doing the work yourself. JMHO.

In addition to my post above, im not going to get to deep in it right away. The only reason i got the whole idea in my head is because i seen i could bore out my cylinders, install dome pistons and get new gaskets for about $300(minus tuning)

Upon seeing head work is the most important thing, and the most costly, im pry gonna wait and gather parts and knowledge over the summer and do all the work next winter.(such as find 06+ heads and correct pistons for a good price)

I still plan on having the bike dyno tuned in the spring, and i might pull the cam cover and replace the shoes/spring in oil pump.

Thanks for all the info!!

#26

97" or 98" big bore jobs do not render the cylinder walls too thin ... the concern has been raised repeatedly over the past few years and repeated debunked ...

The question about early TC vice late TC heads was recently discussed on another thread ... here is a comparison of flow characteristics and a link to a 23-page study on the subject ...

http://www.neverworld.net/socalnetsc...BStudyRel1.pdf

... saw where djl had posted on another thread about the SE cam plate and hydraulic cam chain tensioner / oil pump upgrade ... but, couldn't find the link in a quick 60-second search ... maybe he'll cut and paste the info or point you to the link ...

Good luck coming up with a plan ... sounds like you have some good ideas and some good advice ... you've got plenty of time to create a fire breathing monster ... just get to it in due course ...

Welcome aboard ...

R/

'Chop

The question about early TC vice late TC heads was recently discussed on another thread ... here is a comparison of flow characteristics and a link to a 23-page study on the subject ...

http://www.neverworld.net/socalnetsc...BStudyRel1.pdf

... saw where djl had posted on another thread about the SE cam plate and hydraulic cam chain tensioner / oil pump upgrade ... but, couldn't find the link in a quick 60-second search ... maybe he'll cut and paste the info or point you to the link ...

Good luck coming up with a plan ... sounds like you have some good ideas and some good advice ... you've got plenty of time to create a fire breathing monster ... just get to it in due course ...

Welcome aboard ...

R/

'Chop

#27

Here's djl's post ...

* * *

BTW ... agree that the cast flat-top pistons are as good or better option ... (the larger piston volume of a big bore will increase the compression ratio (CR) over stock bore CR) ...

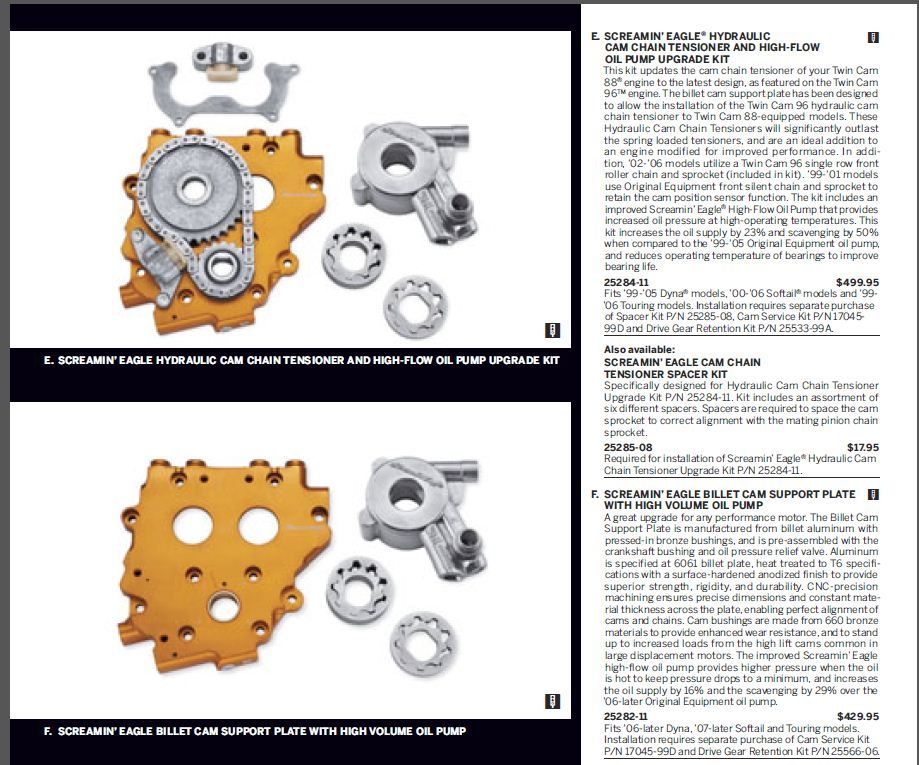

The hydraulic conversion (25284-11) converts the early spring loaded tensioners to hydraulic tensioners and the tensioner shoe is a different material. The kit you linked is the "hybrid" kit that will allow the use of early cams but still runs the early Morse inner chain; not a roller chain. You can run gears with that kit as well.

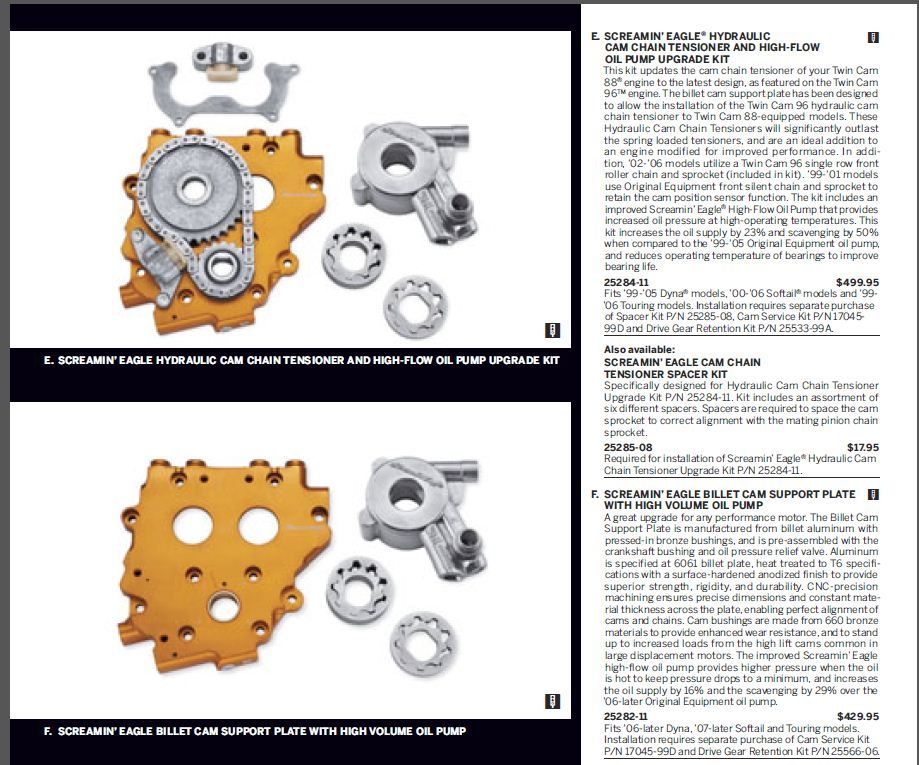

The other kit (25282-11) is the billet plate and upgraded oil pump only; the upgrade for the '05 and later models. You will need the rest of the parts to complete the conversion; outer and inner roller chains, outer sprockets, outer and inner tensioners, cam spacer kit and fasteners since your bike is a 2001 model. You can run gear drives with that kit as well but will need "conversion" cams.

If you want to run gear drives, you can run them in the OEM cam plate but the upgraded oil pump will not retrofit to the early cam plate. You can install the Baisley spring to get a boost in idle oil pressure. The early plate with the Baisle spring is an adequate setup.

Crank runout is measured at the pinion shaft with a dial indicator and should total runout should not exceed .003" to run gear drives. There are under and over size gears available to set the gear backlash within acceptable limits but runout is what it is and it would not be adviseable to run gears if crank runout is excessive.

The other kit (25282-11) is the billet plate and upgraded oil pump only; the upgrade for the '05 and later models. You will need the rest of the parts to complete the conversion; outer and inner roller chains, outer sprockets, outer and inner tensioners, cam spacer kit and fasteners since your bike is a 2001 model. You can run gear drives with that kit as well but will need "conversion" cams.

If you want to run gear drives, you can run them in the OEM cam plate but the upgraded oil pump will not retrofit to the early cam plate. You can install the Baisley spring to get a boost in idle oil pressure. The early plate with the Baisle spring is an adequate setup.

Crank runout is measured at the pinion shaft with a dial indicator and should total runout should not exceed .003" to run gear drives. There are under and over size gears available to set the gear backlash within acceptable limits but runout is what it is and it would not be adviseable to run gears if crank runout is excessive.

BTW ... agree that the cast flat-top pistons are as good or better option ... (the larger piston volume of a big bore will increase the compression ratio (CR) over stock bore CR) ...

Last edited by SURFOR Chop; 01-28-2013 at 09:47 PM.

#28

No worries on 98" bore; plenty running around with 20K and more miles with no issues. If there are issues they haven't shown up yet. You just won't be able to use OEM pistons but there are aftermarket pistons available from Wiseco, CP, MTC to name a few.

CYCO makes a replacement tensioner shoe; different material and cheaper than OEM replacements.

http://www.harleydavidsontensioner.com/

Check the Baisley website for the oil pressure relief valve spring.

http://baisley.com/oil_spring_product.htm

Kudos to you for taking on the project. You will need the service manual; not a Clymer manual but the MoCo manual which is far superior to the others. I would also recommend getting the parts manual as well. The isometric drawings come in handy when trying to remember assembly details.

As for machine work, when you finally get around to it, I would suggest sending heads and cylinders to BigBoyz or the porter of your choice. I know you don't plan on porting the heads but these guys will cc the chambers and balance, deck the heads for compression and do the SERDI valve job. They will also bore your cylnders to fit the pistons and gap the rings. You can send the pistons or they will buy them for you. You get the parts back and put it together.

Good luck.

CYCO makes a replacement tensioner shoe; different material and cheaper than OEM replacements.

http://www.harleydavidsontensioner.com/

Check the Baisley website for the oil pressure relief valve spring.

http://baisley.com/oil_spring_product.htm

Kudos to you for taking on the project. You will need the service manual; not a Clymer manual but the MoCo manual which is far superior to the others. I would also recommend getting the parts manual as well. The isometric drawings come in handy when trying to remember assembly details.

As for machine work, when you finally get around to it, I would suggest sending heads and cylinders to BigBoyz or the porter of your choice. I know you don't plan on porting the heads but these guys will cc the chambers and balance, deck the heads for compression and do the SERDI valve job. They will also bore your cylnders to fit the pistons and gap the rings. You can send the pistons or they will buy them for you. You get the parts back and put it together.

Good luck.

#29

Thanks for all the info!

Im going to keep this thread very handy for when i get around to doing it.

Even though I don't plan on doing the upgrade soon, i am on the hunt for 06+ heads.

The difficult part for me is my engine is the natural silver/grey, whereas black is more common, so it may be more difficult to come by some heads.

If I keep my eye out im sure ill find a deal sooner or later.

Do you know what piston brand fuel moto uses on there kit, I am not partial myself to any brand myself so whatever has the best feedback would be my choice.

Would i want cast or forged?

I've read That cast are favored more..

I'm on the hunt for a service manual also,

Also, I'm assuming SERDI is the competition valve job? but what does it stand for.

I think im better off planning the build out fully instead of starting to rip it apart right away.

Plan so far

Bore cylinders to 98" with flat top pistons

06+ heads with a valve job

oil pump spring upgrade

Cyco tensioner pads.

I don't think adjustable pushrods were installed, I'm assuming that would be a good idea?

Thanks!

Im going to keep this thread very handy for when i get around to doing it.

Even though I don't plan on doing the upgrade soon, i am on the hunt for 06+ heads.

The difficult part for me is my engine is the natural silver/grey, whereas black is more common, so it may be more difficult to come by some heads.

If I keep my eye out im sure ill find a deal sooner or later.

Do you know what piston brand fuel moto uses on there kit, I am not partial myself to any brand myself so whatever has the best feedback would be my choice.

Would i want cast or forged?

I've read That cast are favored more..

I'm on the hunt for a service manual also,

Also, I'm assuming SERDI is the competition valve job? but what does it stand for.

I think im better off planning the build out fully instead of starting to rip it apart right away.

Plan so far

Bore cylinders to 98" with flat top pistons

06+ heads with a valve job

oil pump spring upgrade

Cyco tensioner pads.

I don't think adjustable pushrods were installed, I'm assuming that would be a good idea?

Thanks!

#30

I went with Screamin Eagle "perfect fit" pushrods ... I just see no reason to use adjustable pushrods (especially if you have the rocker boxes removed to swap out the heads) ... in my view it just introduces another potential point of failure ...

Since I installed SE MCR Performance heads on my motor, the 'deck height' was altered (so I could not reuse the stock pushrods, otherwise I would have) ...

As someone else recommended (djl?) ... I also recommend swapping your pipes for a good 2-into-1 exhaust ... like V&H Pro Pipe or D&D Fat Cat ...

Since I installed SE MCR Performance heads on my motor, the 'deck height' was altered (so I could not reuse the stock pushrods, otherwise I would have) ...

As someone else recommended (djl?) ... I also recommend swapping your pipes for a good 2-into-1 exhaust ... like V&H Pro Pipe or D&D Fat Cat ...