Compensator issues

#1

#2

The following 3 users liked this post by Ohio HD:

#3

The biggest issue I have read about the early Twin Cam compensators (before the "upgrade" in 2007+ models) is that sometimes the the comp nut will come loose.

It was a big enough problem that HD covered it in a Tech Tip.

Tech Tip- TT122, dated 10/29/03, "Engine Noise and Vibration Complaints"- It discussed engine noise & vibrations could be caused by a loose compensator nut. The loose nut could be due to bad clamp load on the comp nut.

If no indications of poor clamp load and the comp nut is loose, they suggested to reassembled with clean threads, Threadlocker 262, and retorque to 150-165 ft lbs

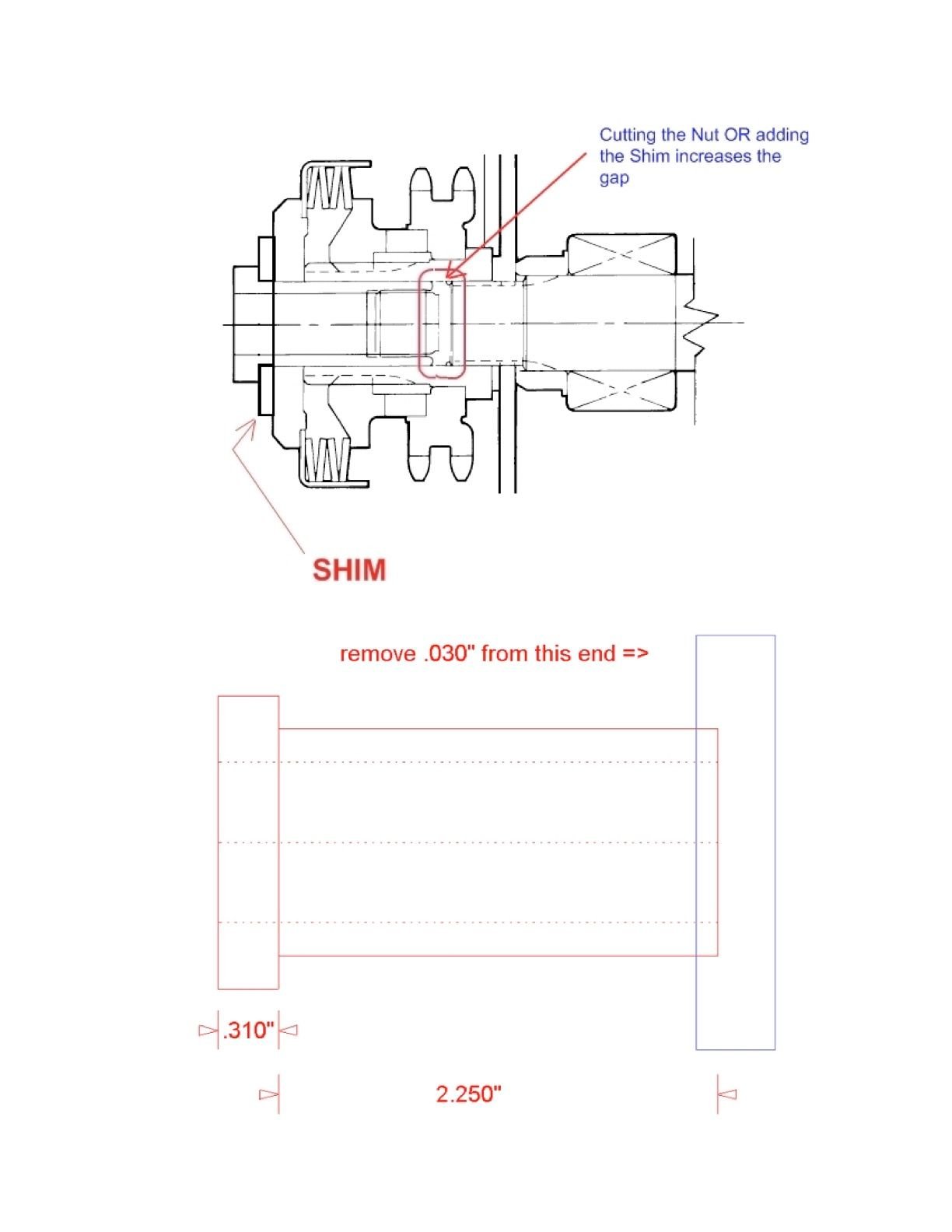

If the comp nut is tight, they suggested it may be a clamp load issue. They recommend, "Try adding a 24033-70 shim under the head of the compensating nut (p/n 40392-91) and re-assemble as described above."

They also changed the torque spec from 150-165 ft lbs to basically torquing the comp nut to 75 ft lbs, then tightening an additional 45° - 50°, with a max of 50 °. This came out in a Service Bulletin, M-1170, dated 5/27/05.

Many experienced techs ignore the shim recommended by the MoCo. Any time they have to work on an early twin Cam Compensator, they just trim the comp nut bottom .030". That way it is a non-issue. If someone takes it apart, unfamiliar with TT122, they can just reassemble per the Service Manual, and they are golden. They don't have to find a shim, not mentioned in the Service Manual and wonder, what's with this shim? Should there should be a shim? Where is it supposed to go? etc, etc....

---see below---

Last edited by hattitude; Yesterday at 04:43 PM.

The following users liked this post:

Ohio HD (Yesterday)

#4

The biggest issue I have read about the early Twin Cam compensators (before the "upgrade" in 2007+ models) is that sometimes the the comp nut will come loose.

It was a big enough problem that HD covered it in a Tech Tip.

Tech Tip- TT122, dated 10/29/03, "Engine Noise and Vibration Complaints"- It discussed engine noise & vibrations could be caused by a loose compensator nut. The loose nut could be due to bad clamp load on the comp nut.

If no indications of poor clamp load and the comp nut is loose, they suggested to reassembled with clean threads, Threadlocker 262, and retorque to 150-165 ft lbs

If the comp nut is tight, they suggested it may be a clamp load issue. They recommend, "Try adding a 24033-70 shim under the head of the compensating nut (p/n 40392-91) and re-assemble as described above."

They also changed the torque spec from 150-165 ft lbs to basically torquing the comp nut to 75 ft lbs, then tightening an additional 45° - 50°, with a max of 50 °. This came out in a Service Bulletin, M-1170, dated 5/27/05.

Many experienced techs ignore the shim recommended by the MoCo. Any time they have to work on an early twin Cam Compensator, they just trim the comp nut bottom .030". That way it is a non-issue. If someone takes it apart, unfamiliar with TT122, they can just reassemble per the Service Manual. and they are golden. They don't have to find a shim, not mentioned in the Service Manual and wonder, what's with this shim? Should there should be a shim? Where is it supposed to go? etc, etc....

The following users liked this post:

hattitude (Yesterday)

#5

The following users liked this post:

Ohio HD (Yesterday)

#6

#8

The shim we are talking about, which is discussed in the TT122, goes under the head of the comp bolt, so it doesn't bottom out and have stacking issues.... it's labelled "shim" in the 2nd diagram I posted.

The following users liked this post:

Ohio HD (Yesterday)

#9

The following users liked this post:

hattitude (Yesterday)

Thread

Thread Starter

Forum

Replies

Last Post