Correct torque setting

#1

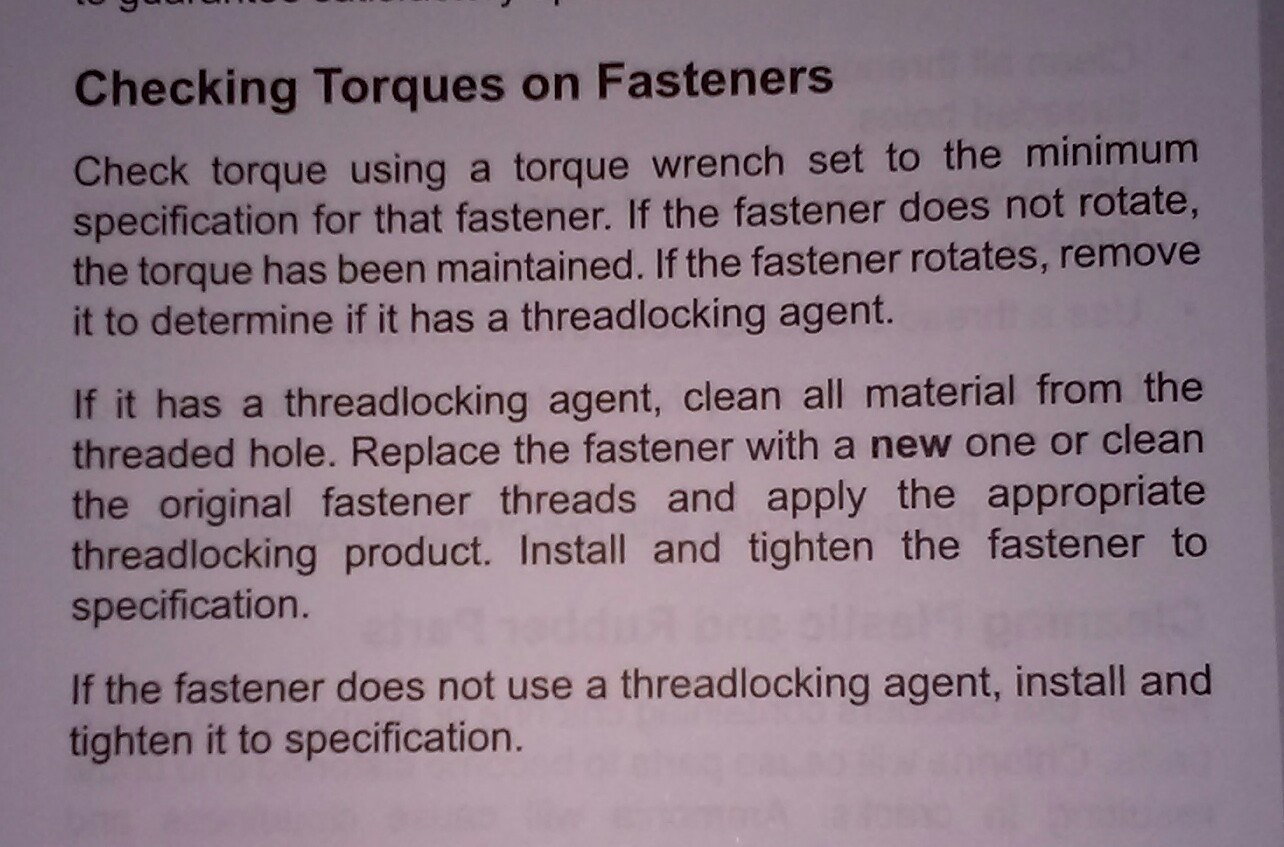

When it comes to using a torque wrench to tighten a bolt or nut, the manual states a given range to set it to. The range of tightness seems to vary quite a bit. I believe the wide range is because of the bolt's material strength (it's composition), if there's any lube involved, etc. But what I'm wondering is if I should just go with the middle of the range like I have been, or maybe go with the low end of the range stated in the manual.

#3

think of a bolt as a rubber band. engineers factor in application and then size of the fastener and the rated torque range the mfg says it will support. if too tight, thread failure can happen and if too loose the the connection can fail. this is with new unused fasteners. the manual does not know what you are doing so specifies a range that the mfg say will work with the application. if the fastener is used, it theoretically is stretched and will require more applied torque to achieve a set amount of clamping force. the mfg say do not exceed the upper limit or damage can be done.

as far as lube, nothing to do with it. if you use a lube, you must factor in 10>20% adjustment in torque (reduction) so you do not exceed the highest suggested limit, unless the manual says to use a lube and torque to a set level. the head bolts is an example. some fasteners (increasing in numbers) require a set torque and a certain degree of additional rotation regardless of torque numbers.

as far as lube, nothing to do with it. if you use a lube, you must factor in 10>20% adjustment in torque (reduction) so you do not exceed the highest suggested limit, unless the manual says to use a lube and torque to a set level. the head bolts is an example. some fasteners (increasing in numbers) require a set torque and a certain degree of additional rotation regardless of torque numbers.

The following users liked this post:

oldtoad (03-26-2019)

#4

#5

#7

Trending Topics

#8

#10