**Twincam woodshed DIY crank job. PICS.**

#1

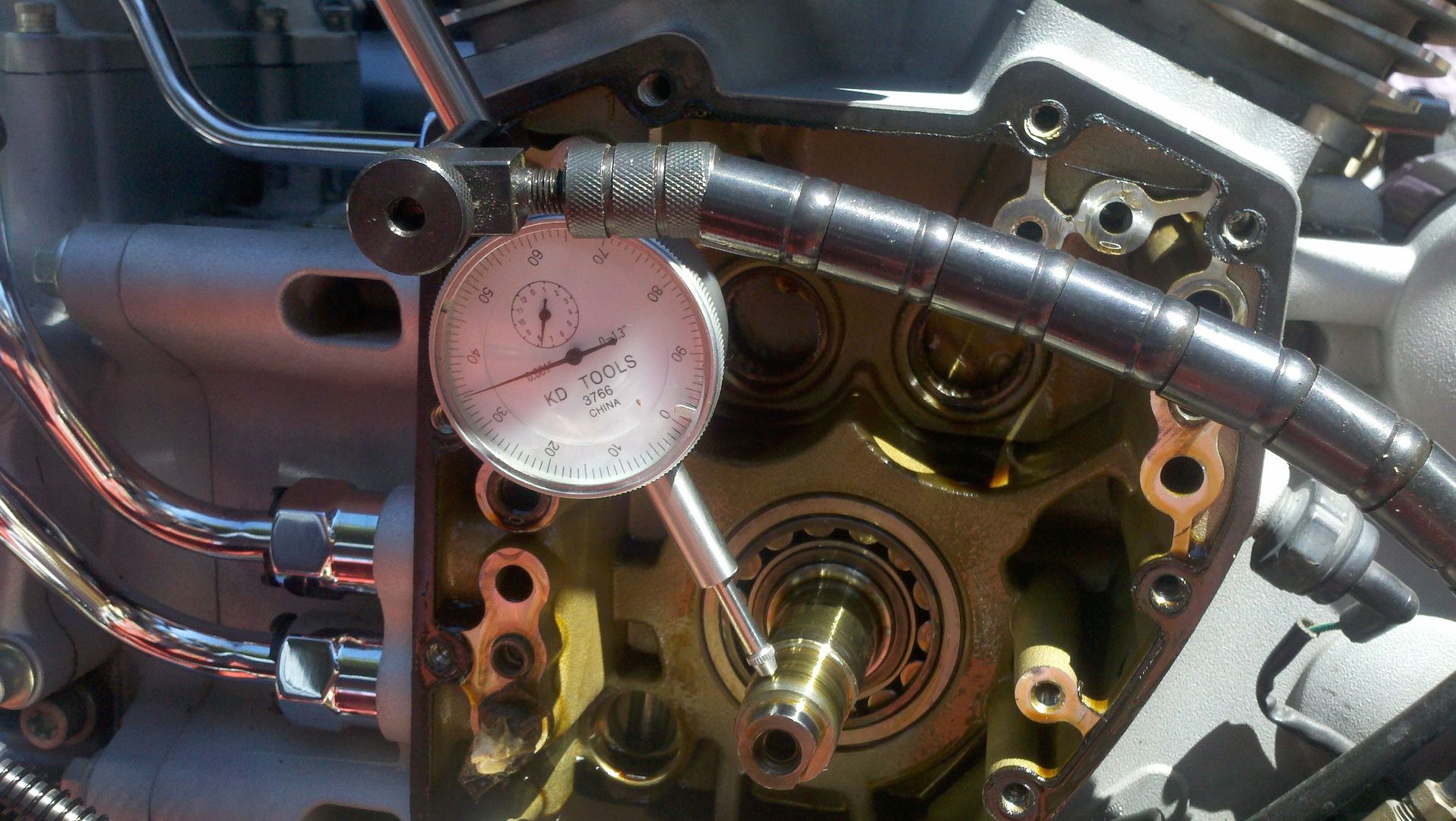

Last sumer I had a strange vibration in my bottom end that under the right conditions would travel from my seat all the way up into the bars. It wasn't heavy or audible. I had suspected a wrist pin bushing. Unfortunately I was correct. This led me down the rabbit trail to the discovery how flawed the 07+ twin cam bottom end is. I am not good with making DIY threads but I have plenty of pics to show. I have limited space at home. Basically a 10x14 woodshed. Once the motor was out I took it to work and tore into it after hours. Not 1 HD specialty tool was used in the making of this motor. No bike lift or table. One reason for this thread was to take some of the mystery out of the Twin cam bottom end. They are pretty simple and if you take the time it can be done. I did go over board on the internal components and to save money OEM parts can be used for this build. I hope this thread serves to help others tear into their engine. Plenty of forum members helped me along the way.

This is my initial thread when I was figuring all this stuff out and the members that gave their 2 cents: https://www.hdforums.com/forum/gener...2007-fxst.html

Here is the bike entering the woodshed for teardown.

This is my initial thread when I was figuring all this stuff out and the members that gave their 2 cents: https://www.hdforums.com/forum/gener...2007-fxst.html

Here is the bike entering the woodshed for teardown.

Last edited by soft 02; 05-29-2013 at 12:10 AM.

#2

#3

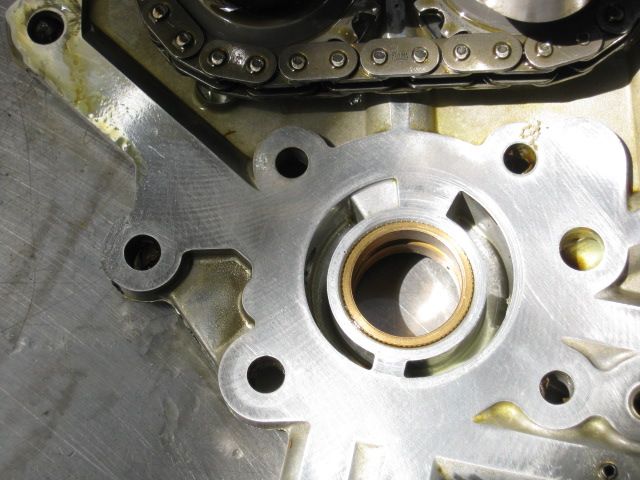

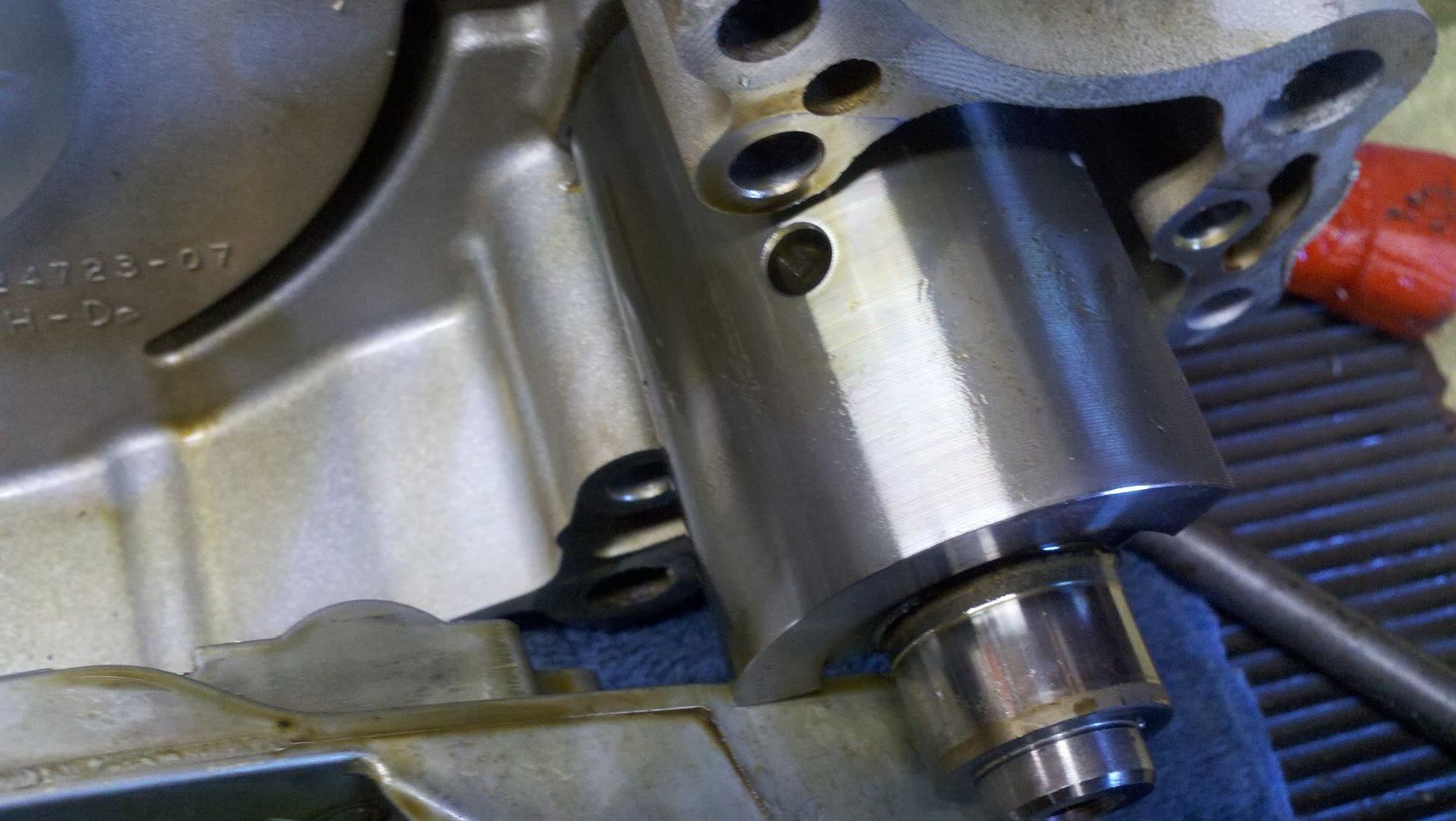

I then went on a search for a replacement bushing only to find out that a $20 bushing is not serviceable and the crank needs to be replaced or serviced by a crank shop. In the end I chose Darkhorse for reasons to be explained later.

#4

#5

#6

#7

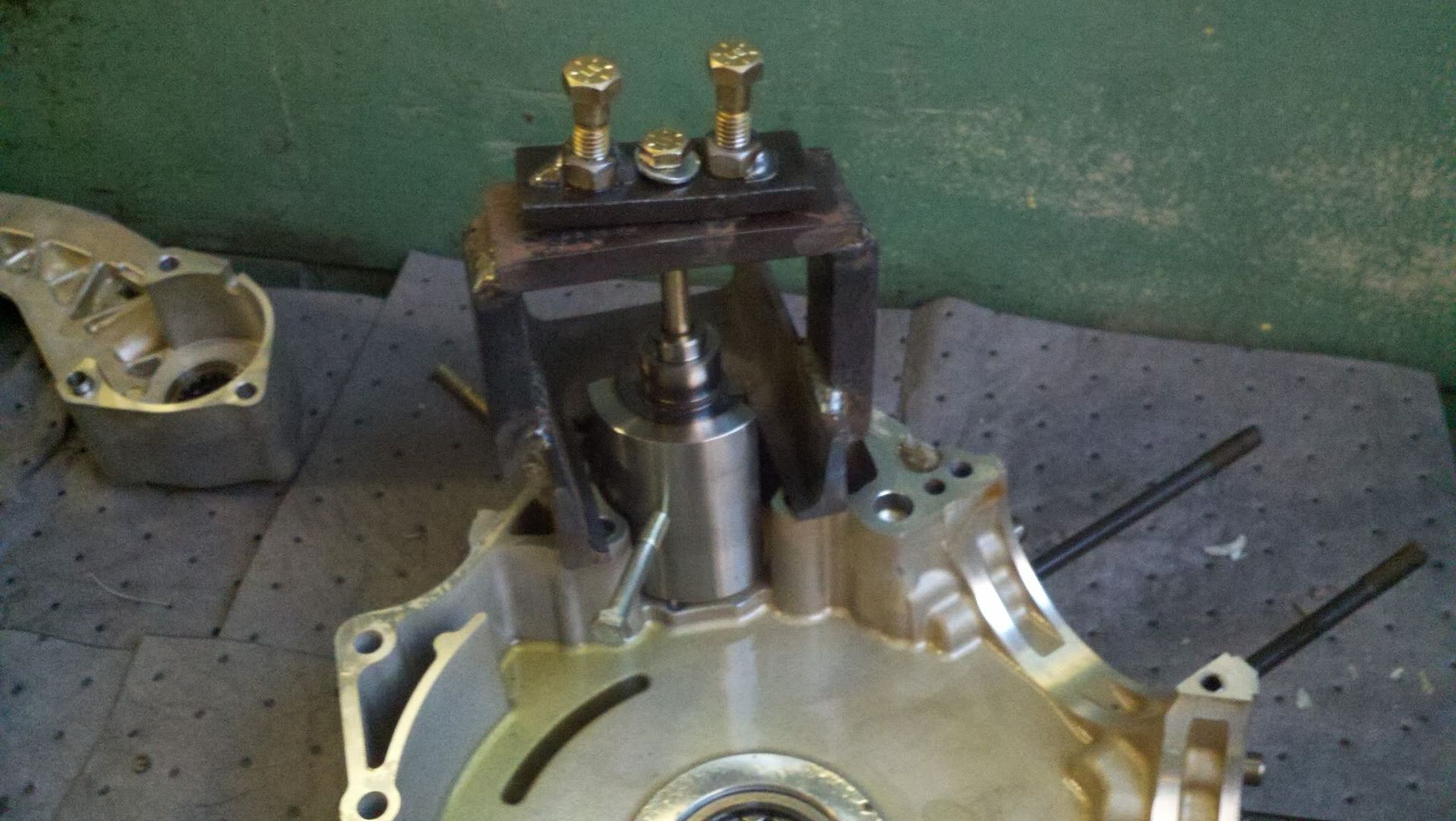

Now I begin splitting the cases and explore my options for parts and start selling stuff on ebay and craigslist.

Trending Topics

#8

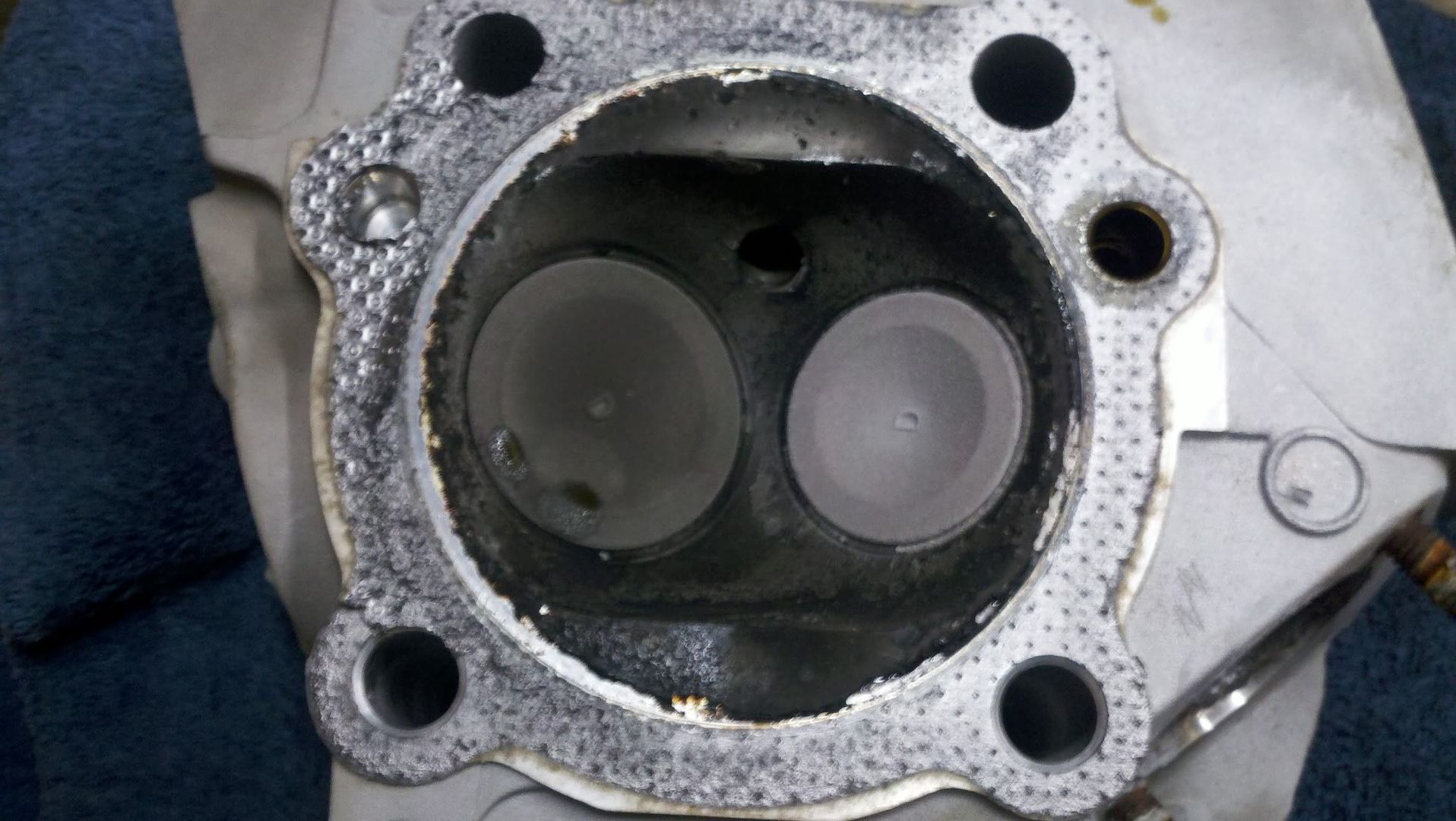

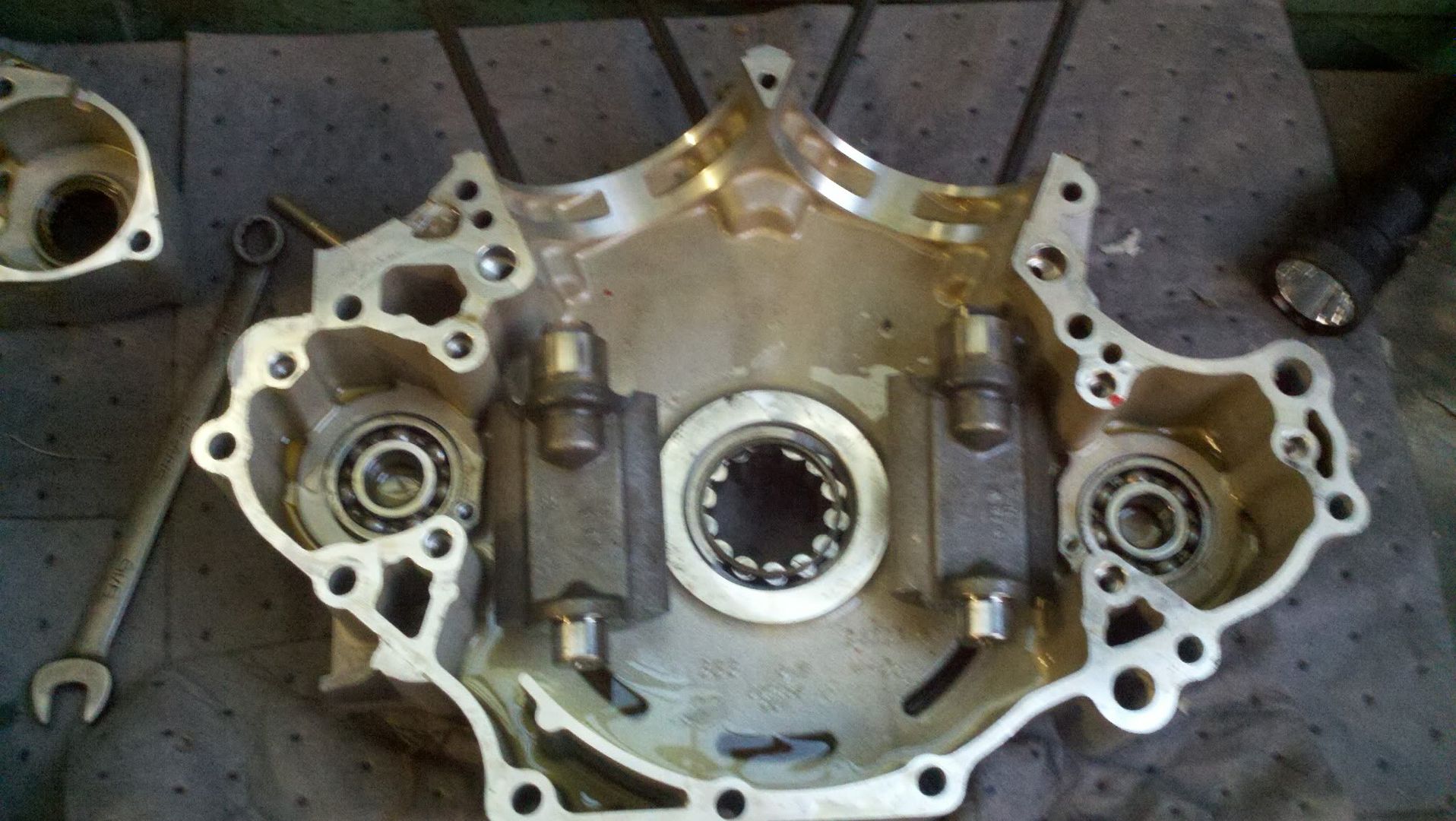

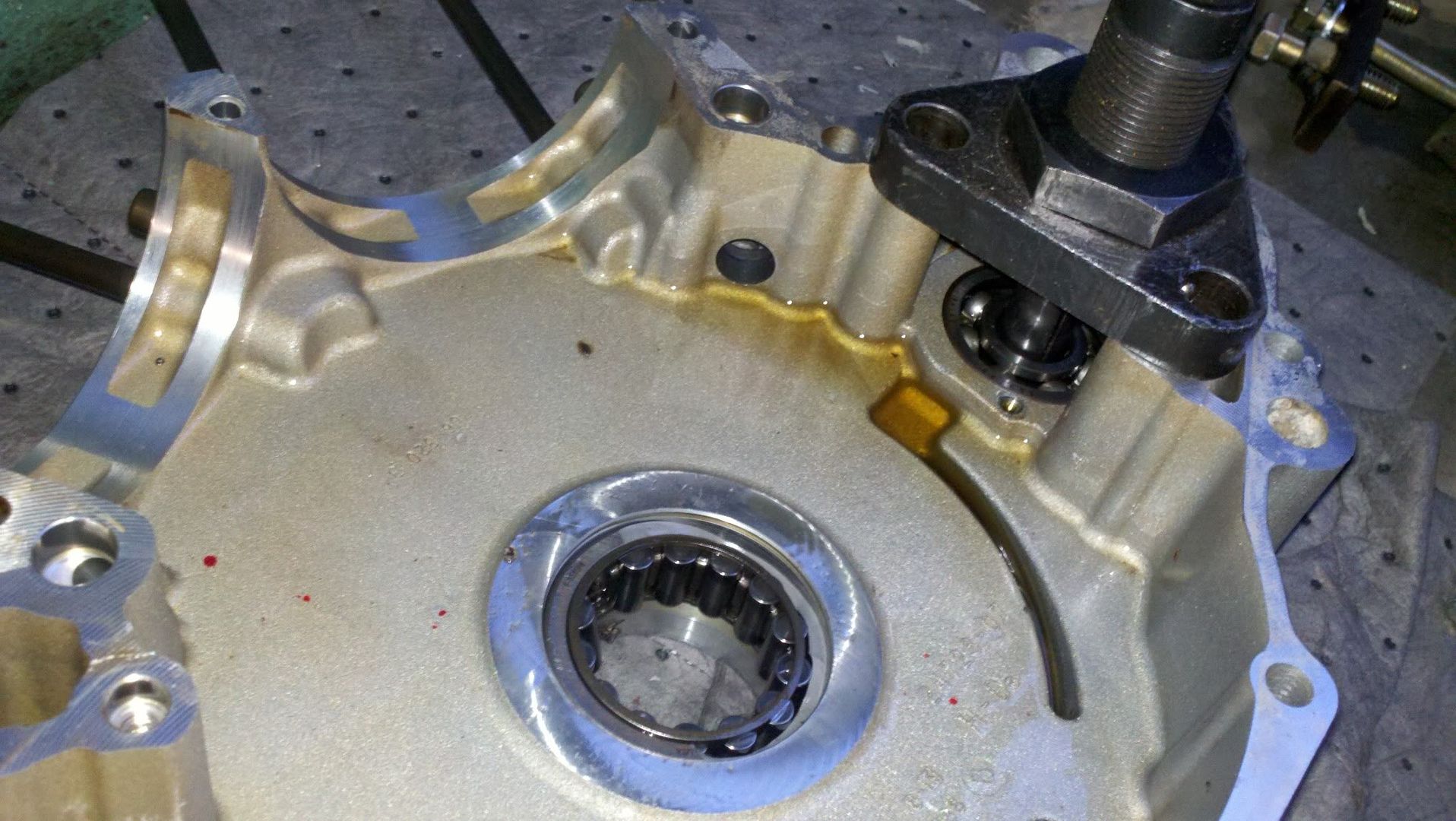

She is split. A little effort with the rubber mallet and its appart. At this point i'm not concerned with cleanliness or damaged seals or bearings as all will be replaced. One pic I never took was all the little baggies full of bolts and a sharpie indicating where they go.

Careful machined parts are sharp!

Careful machined parts are sharp!

#9

#10