Couple Engine Build Questions

#1

I have a pretty good understanding of what can be done and what needs to be done when doing a top-end engine build. I am planning a couple top end engine builds and have a couple questions.

1. Crank run-out: What is this, why is it important, how do you check it, what is out to much, if it is out to much what does it affect, if its out to much what do you do about it.

2. I understand the basics of cam #'s (ie. lift and intake closing), but how does the cam lobe angle #'s affect how a cam works and what do they mean when they say a cam ramps fast or slow.

Look forward to the info.

1. Crank run-out: What is this, why is it important, how do you check it, what is out to much, if it is out to much what does it affect, if its out to much what do you do about it.

2. I understand the basics of cam #'s (ie. lift and intake closing), but how does the cam lobe angle #'s affect how a cam works and what do they mean when they say a cam ramps fast or slow.

Look forward to the info.

#2

I have a pretty good understanding of what can be done and what needs to be done when doing a top-end engine build. I am planning a couple top end engine builds and have a couple questions.

1. Crank run-out: What is this, why is it important, how do you check it, what is out to much, if it is out to much what does it affect, if its out to much what do you do about it.

2. I understand the basics of cam #'s (ie. lift and intake closing), but how does the cam lobe angle #'s affect how a cam works and what do they mean when they say a cam ramps fast or slow.

Look forward to the info.

1. Crank run-out: What is this, why is it important, how do you check it, what is out to much, if it is out to much what does it affect, if its out to much what do you do about it.

2. I understand the basics of cam #'s (ie. lift and intake closing), but how does the cam lobe angle #'s affect how a cam works and what do they mean when they say a cam ramps fast or slow.

Look forward to the info.

http://www.andrewsproducts.com/PDF_f...99_Gear-01.pdf

2. Not sure what you mean by cam angle numbers but the number most look at when selecting a cam is the intake close event. Early close, higher cranking compression and possible need for compression releases. As for ramps being slow or fast, it is just that the ramp is steep and moves the lifter fast or the ramp is less steep and moves the lifter slower. Fast ramps, like Woods cams usually mean noisier valve trains.

Last edited by djl; 09-17-2010 at 03:29 PM.

#3

Click HERE for proper way to measure crank run out. Watch the embedded videos.

The run out on a HD crank needs to be checked, because the crank is a three piece deal with the pieces pressed together. It is NOT a solid piece like in a car. Sometimes the assembly 'twists' and THAT induces 'run out'. The run out is a good check to see if all is in order with ones crank.

MOCO warranty replacement is .012 of run out. On 88s, the warranty replacement was .0035. Instead of fixing the problem, the MOCO upped the specs. Twisted cranks is NOT an epidemic, but it DOES happen. Happened to me on a stock bike.

IMHO, about .0035 and up is when one needs to start worrying.

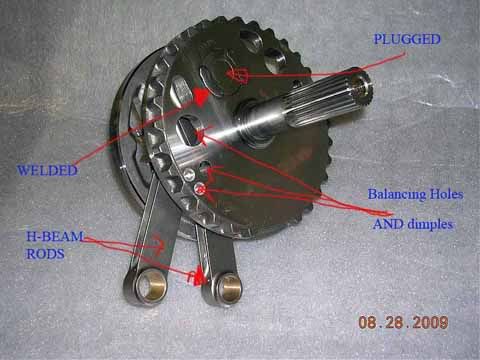

My crank, now, has .0005 of run out and is welded, plugged, balanced, and has upgraded H Beam rods. A bit overkill, but once I had to tear out the bottom end... I wanted to do it only ONE TIME.

The run out on a HD crank needs to be checked, because the crank is a three piece deal with the pieces pressed together. It is NOT a solid piece like in a car. Sometimes the assembly 'twists' and THAT induces 'run out'. The run out is a good check to see if all is in order with ones crank.

MOCO warranty replacement is .012 of run out. On 88s, the warranty replacement was .0035. Instead of fixing the problem, the MOCO upped the specs. Twisted cranks is NOT an epidemic, but it DOES happen. Happened to me on a stock bike.

IMHO, about .0035 and up is when one needs to start worrying.

My crank, now, has .0005 of run out and is welded, plugged, balanced, and has upgraded H Beam rods. A bit overkill, but once I had to tear out the bottom end... I wanted to do it only ONE TIME.

Last edited by wurk_truk; 09-17-2010 at 06:50 PM.

#5

Thanks for the info guys.

djl, what is was asking regarding cam angle was in regards to the cam "lobe centerline angle". some manf. give this in there specs, some don't. was curious what this # was and what it meant as to how a cam performs. I have read that Woods cams are fast ramping thus creating additional valve train noise, how do you know if a particular cam is "fast" or "slow" ramping from its specs?

Thanks again

djl, what is was asking regarding cam angle was in regards to the cam "lobe centerline angle". some manf. give this in there specs, some don't. was curious what this # was and what it meant as to how a cam performs. I have read that Woods cams are fast ramping thus creating additional valve train noise, how do you know if a particular cam is "fast" or "slow" ramping from its specs?

Thanks again

#6

Apologies for the long post but I am not sure if you are referring to lobe centerline or lobe separation angle and both are not explained in 25 words or less. The follwing is an excerpt from an article that I refer to from time to time;

Lobe Centerline: Lobe Center lines give you a relative perspective of how advanced or retarded a cam is in relation to top dead center (TDC). Harley cam profiles typically have an intake center line from 98 to 108 degrees. An intake centerline of 98 is considered to be the most advanced and generally gives the most torque. A centerline of 108 will give power in the upper rpm range. An exhaust centerline of 112 is the most advanced while the 102 is the most retarded. Again an advanced lobe will give power in the lower rpm range while the retarded lobe will have it's power range extended in the rpm range. For practical terms, most cams for Harley are in the range of 96-108 on intake and 112-102 on the exhaust.

Tailoring the valve opening and closing points on an actual camshaft is accomplished by varying the lobe centerline location, changing the LSA, and refining the profile shape itself. Advancing the cam moves both the intake and exhaust in an equal amount, resulting in earlier valve timing events. Engines typically respond better with a few degrees of advance, probably due to the importance of the intake closing point on performance. For racing, advanced cams benefit torque converter stall, improve off-the-line drag race launches, and help circle-track cars come off the corner. Cam companies often grind their street cams advanced (4 degrees is typical), which allows the end-user to receive the benefits of increased cylinder pressure yet still install the cam using the standard timing marks. Increasing the intake lobe center line from 104 to 106 degrees is considered retarding. All events will take place later in the engine cycle. Retarding the cam causes the intake valve to open and close later. This will reduce cylinder pressure which reduces the low speed performance of the engine.

Advancing the intake and retarding the exhaust “closing up the centers” increases overlap and should move the power up in the RPM range, usually at the sacrifice of bottom end power. The result would be lower numerical values on both intake and exhaust lobe centers.

Retarding the intake and advancing the exhaust “spreading the centers” decreases overlap and should result in a wider power band at the sacrifice of some top end power. This condition would be indicated by higher numerical values on both intake and exhaust lobe centers. By moving only one cam the results are less predictable, but usually it is the intake that is moved to change power characteristics since small changes here seem to have a greater effect.

Lobe Separation Angle: Lobe separation is the angle between the center bump of the intake lobe and its counterpart on the exhaust lobe. Think of it like the two points on a pair of scissors relative to the hinge in the middle. If the scissors are nearly closed, you can cut well as long as what you are cutting is thin. To cut thick stuff, you open wider, but have less leverage, so it can be harder to get the done. The same principle applies with separation on cam lobes. Typically, lobe separation for street cams runs between 97 and 108 (camshaft) degrees. The relationship between intake and exhaust is ground in the cam and can’t be altered by advancing or retarding the overall cam timing.

As a guideline, if the rest of the numbers are comparable, a cam with a lobe that is less separate, i.e an LSA of 98-103 degrees will offer a broader spread of power and tend to produce power at the low end, while wide lobes make for a more “cammy” cam, coming on harder and later in the game.

LSA and lift affect the "sound" and idle quality. Generally, smaller lobe separation angles cause an engine to produce more midrange torque and high rpm power, and be more responsive, while larger lobe separation angles result in broader torque, improved idle characteristics, and more peak horsepower.

A “tight” lobe separation angle of 103 degrees or less creates more valve overlap, which helps create that lumpy idle characteristic of big camshafts. The tighter LSAs are, the more likely problematical exhaust reversion into the intake will occur. Put simply, we can say that a tight LSA cam produces a power curve that is, for want of a better description, more "punchy." At low rpm when off the cam, it runs rougher, and it comes on the cam with more of a "bang." Narrow LSAs tend to increase midrange torque and result in faster revving engines. Generally, smaller lobe separation angles cause an engine to produce more midrange torque and high rpm power, and be more responsive. Typically, however, small lobe center numbers (more overlap) equates to more midrange power at the expense of top-end power. Probably the most significant factor to the engine tuner though is a tight LSA’s intolerance of exhaust system backpressure. Remember, during the overlap period both valves are open. If there’s any exhaust backpressure or if the exhaust port velocities are too low it will encourage exhaust reversion. A cam with 102 degrees of lobe separation angle will have more overlap and a rougher idle than one with 108 degrees, but it'll usually make more midrange power. A tighter lobe has more overlap. A tighter centerline starts torque curve sooner, and doesn't give a wide powerband.

For higher low/midrange power, a cam with shorter duration, higher lift, and a narrower LSA is commonly prescribed.

A wider lobe doesn't start the torque curve sooner, but it continues to make torque longer and has a broader powerband. Wide LSAs result in wider power bands and more peak torque at higher RPM’s, at the price of somewhat lazier initial response. Larger LSAs result in broader torque, improved idle characteristics, and more peak horsepower. A wider lobe doesn't start the torque curve sooner, but it continues to make torque longer and has a broader powerband. A street engine with a wide LSA has higher vacuum and a smoother idle. Big numbers (less overlap) will give more top end, sacrificing midrange. A cam on wide centerlines produces a wider power band. It will idle smoother and produce better vacuum, but the price paid is a reduction in output throughout the working rpm range.

As the spread between the lobes tightens, the lobe-separation number gets smaller and overlap increases since the centerlines of the two lobes are coming closer together. A larger lobe separation angle means less overlap because the lobe centerlines are moving farther apart.

For a given engine displacement, a wide LSA will help top end power if there is enough duration to support the wide LSA. A wide LSA combined with insufficient duration may not result in improved top end power.

Narrow LSA (98-103)

Moves Torque to Lower RPM

Increase midrange Torque

Increases Maximum Torque

Faster revving engine and more responsive

Narrow Power band

Builds Higher Cylinder Pressure

Increase Chance of Engine Knock

Increase Cranking Compression

Increase Effective Compression

Idle Vacuum is Reduced

Idle Quality Suffers (lumpy idle characteristic)

Open Valve-Overlap Increases

Closed Valve-Overlap Increases

Decreases Piston-to-Valve Clearance

Wide LSA (104-108)

Raise Torque to Higher RPM

Reduces Maximum Torque

Broadens Power Band

Lazier initial response

More peak Horsepower

Reduce Maximum Cylinder Pressure

Decrease Chance of Engine Knock

Decrease Cranking Compression

Decrease Effective Compression

Idle Vacuum is Increased

Idle Quality Improves

Open Valve-Overlap Decreases

Closed Valve-Overlap Decreases

Increases Piston-to-Valve Clearance

Lobe Centerline: Lobe Center lines give you a relative perspective of how advanced or retarded a cam is in relation to top dead center (TDC). Harley cam profiles typically have an intake center line from 98 to 108 degrees. An intake centerline of 98 is considered to be the most advanced and generally gives the most torque. A centerline of 108 will give power in the upper rpm range. An exhaust centerline of 112 is the most advanced while the 102 is the most retarded. Again an advanced lobe will give power in the lower rpm range while the retarded lobe will have it's power range extended in the rpm range. For practical terms, most cams for Harley are in the range of 96-108 on intake and 112-102 on the exhaust.

Tailoring the valve opening and closing points on an actual camshaft is accomplished by varying the lobe centerline location, changing the LSA, and refining the profile shape itself. Advancing the cam moves both the intake and exhaust in an equal amount, resulting in earlier valve timing events. Engines typically respond better with a few degrees of advance, probably due to the importance of the intake closing point on performance. For racing, advanced cams benefit torque converter stall, improve off-the-line drag race launches, and help circle-track cars come off the corner. Cam companies often grind their street cams advanced (4 degrees is typical), which allows the end-user to receive the benefits of increased cylinder pressure yet still install the cam using the standard timing marks. Increasing the intake lobe center line from 104 to 106 degrees is considered retarding. All events will take place later in the engine cycle. Retarding the cam causes the intake valve to open and close later. This will reduce cylinder pressure which reduces the low speed performance of the engine.

Advancing the intake and retarding the exhaust “closing up the centers” increases overlap and should move the power up in the RPM range, usually at the sacrifice of bottom end power. The result would be lower numerical values on both intake and exhaust lobe centers.

Retarding the intake and advancing the exhaust “spreading the centers” decreases overlap and should result in a wider power band at the sacrifice of some top end power. This condition would be indicated by higher numerical values on both intake and exhaust lobe centers. By moving only one cam the results are less predictable, but usually it is the intake that is moved to change power characteristics since small changes here seem to have a greater effect.

Lobe Separation Angle: Lobe separation is the angle between the center bump of the intake lobe and its counterpart on the exhaust lobe. Think of it like the two points on a pair of scissors relative to the hinge in the middle. If the scissors are nearly closed, you can cut well as long as what you are cutting is thin. To cut thick stuff, you open wider, but have less leverage, so it can be harder to get the done. The same principle applies with separation on cam lobes. Typically, lobe separation for street cams runs between 97 and 108 (camshaft) degrees. The relationship between intake and exhaust is ground in the cam and can’t be altered by advancing or retarding the overall cam timing.

As a guideline, if the rest of the numbers are comparable, a cam with a lobe that is less separate, i.e an LSA of 98-103 degrees will offer a broader spread of power and tend to produce power at the low end, while wide lobes make for a more “cammy” cam, coming on harder and later in the game.

LSA and lift affect the "sound" and idle quality. Generally, smaller lobe separation angles cause an engine to produce more midrange torque and high rpm power, and be more responsive, while larger lobe separation angles result in broader torque, improved idle characteristics, and more peak horsepower.

A “tight” lobe separation angle of 103 degrees or less creates more valve overlap, which helps create that lumpy idle characteristic of big camshafts. The tighter LSAs are, the more likely problematical exhaust reversion into the intake will occur. Put simply, we can say that a tight LSA cam produces a power curve that is, for want of a better description, more "punchy." At low rpm when off the cam, it runs rougher, and it comes on the cam with more of a "bang." Narrow LSAs tend to increase midrange torque and result in faster revving engines. Generally, smaller lobe separation angles cause an engine to produce more midrange torque and high rpm power, and be more responsive. Typically, however, small lobe center numbers (more overlap) equates to more midrange power at the expense of top-end power. Probably the most significant factor to the engine tuner though is a tight LSA’s intolerance of exhaust system backpressure. Remember, during the overlap period both valves are open. If there’s any exhaust backpressure or if the exhaust port velocities are too low it will encourage exhaust reversion. A cam with 102 degrees of lobe separation angle will have more overlap and a rougher idle than one with 108 degrees, but it'll usually make more midrange power. A tighter lobe has more overlap. A tighter centerline starts torque curve sooner, and doesn't give a wide powerband.

For higher low/midrange power, a cam with shorter duration, higher lift, and a narrower LSA is commonly prescribed.

A wider lobe doesn't start the torque curve sooner, but it continues to make torque longer and has a broader powerband. Wide LSAs result in wider power bands and more peak torque at higher RPM’s, at the price of somewhat lazier initial response. Larger LSAs result in broader torque, improved idle characteristics, and more peak horsepower. A wider lobe doesn't start the torque curve sooner, but it continues to make torque longer and has a broader powerband. A street engine with a wide LSA has higher vacuum and a smoother idle. Big numbers (less overlap) will give more top end, sacrificing midrange. A cam on wide centerlines produces a wider power band. It will idle smoother and produce better vacuum, but the price paid is a reduction in output throughout the working rpm range.

As the spread between the lobes tightens, the lobe-separation number gets smaller and overlap increases since the centerlines of the two lobes are coming closer together. A larger lobe separation angle means less overlap because the lobe centerlines are moving farther apart.

For a given engine displacement, a wide LSA will help top end power if there is enough duration to support the wide LSA. A wide LSA combined with insufficient duration may not result in improved top end power.

Narrow LSA (98-103)

Moves Torque to Lower RPM

Increase midrange Torque

Increases Maximum Torque

Faster revving engine and more responsive

Narrow Power band

Builds Higher Cylinder Pressure

Increase Chance of Engine Knock

Increase Cranking Compression

Increase Effective Compression

Idle Vacuum is Reduced

Idle Quality Suffers (lumpy idle characteristic)

Open Valve-Overlap Increases

Closed Valve-Overlap Increases

Decreases Piston-to-Valve Clearance

Wide LSA (104-108)

Raise Torque to Higher RPM

Reduces Maximum Torque

Broadens Power Band

Lazier initial response

More peak Horsepower

Reduce Maximum Cylinder Pressure

Decrease Chance of Engine Knock

Decrease Cranking Compression

Decrease Effective Compression

Idle Vacuum is Increased

Idle Quality Improves

Open Valve-Overlap Decreases

Closed Valve-Overlap Decreases

Increases Piston-to-Valve Clearance

Last edited by djl; 09-18-2010 at 11:29 AM.

#7

Join Date: Sep 2009

Location: The Internet (& Dyer, Indiana)

Posts: 7,580

Likes: 0

Received 7 Likes

on

7 Posts

Rather than trying to figure from scratch (cam closings etc), you might do better asking for cam recommendations. Then study those cams to see where they come on at (rpm) and fall off at, what compression they like, etc.

Pay real close attention to what was said above about run-out.

That is a huge factor in any build.

Not sure I'd even proceed on a build with more than .003.

Pay real close attention to what was said above about run-out.

That is a huge factor in any build.

Not sure I'd even proceed on a build with more than .003.

Trending Topics

#8

Rather than trying to figure from scratch (cam closings etc), you might do better asking for cam recommendations. Then study those cams to see where they come on at (rpm) and fall off at, what compression they like, etc.

Pay real close attention to what was said above about run-out.

That is a huge factor in any build.

Not sure I'd even proceed on a build with more than .003.

Pay real close attention to what was said above about run-out.

That is a huge factor in any build.

Not sure I'd even proceed on a build with more than .003.

Thread

Thread Starter

Forum

Replies

Last Post