113 SnS rebuild..

#61

#62

#63

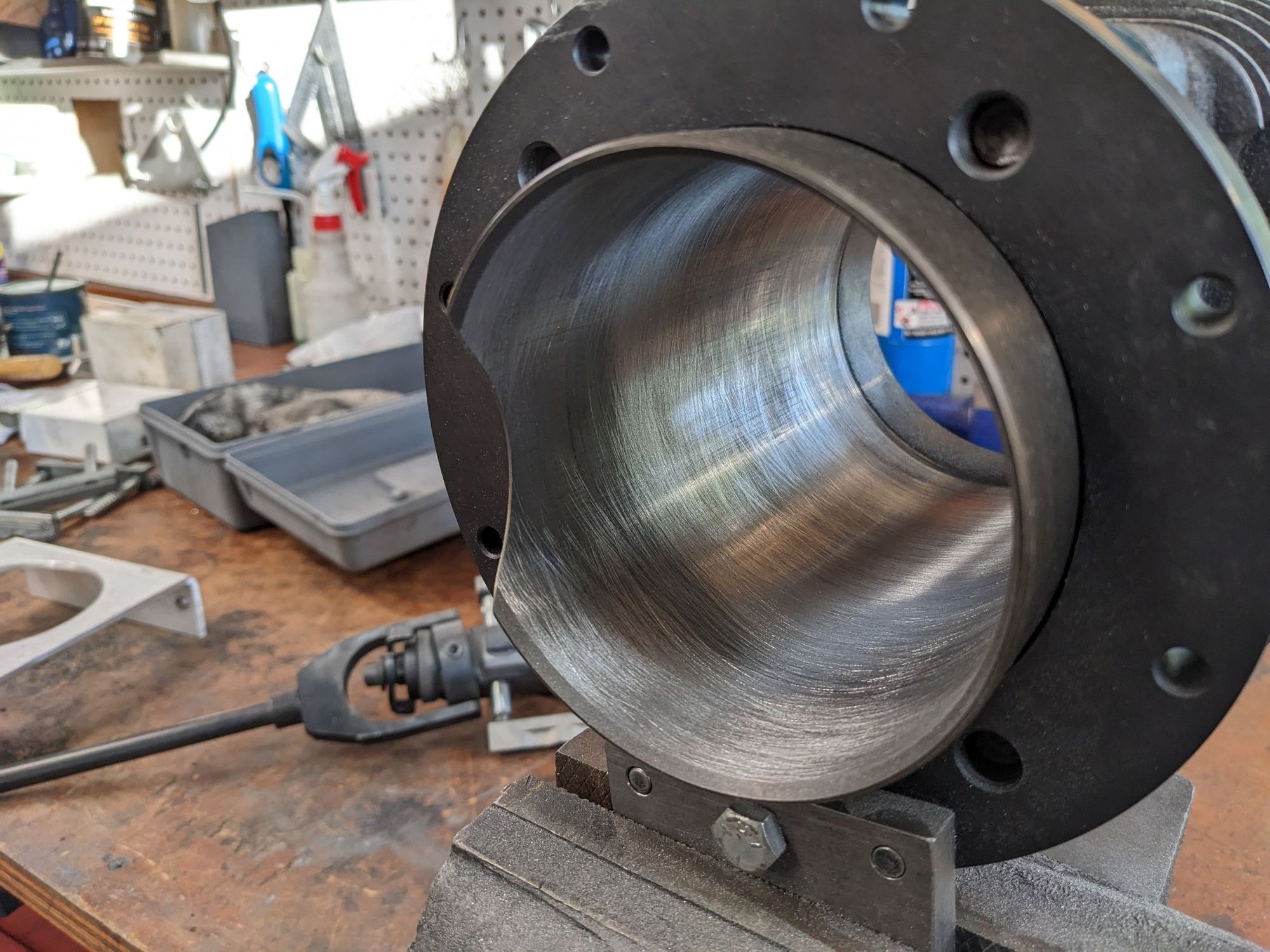

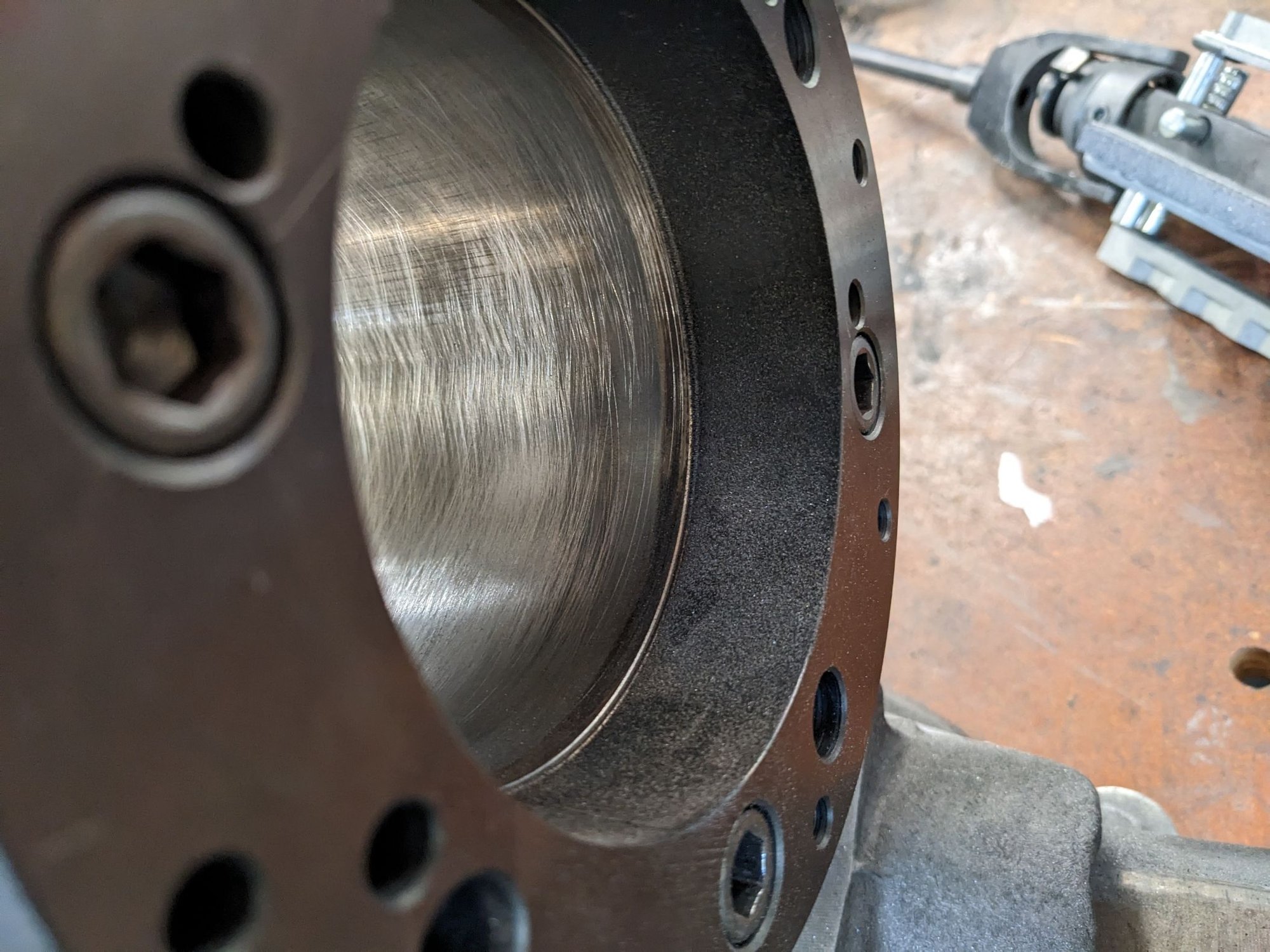

We use a CK15 to do all the cylinders we had a CK10 before this one in the 80s - you put the length of the rod - the bore - and the stroke - what happens is the honing head starts and stops at the correct 60 degrees cross hatch while being flooded with honing oil as we watch the bore temps

made the jig for harley cylinders for the machine to torque the base - then we made ( small platform from a small Bridgeport type machine ) for the Indian and assorted flat head jugs

today we do cast at .003 and some .0035 - hot rods forged .005 / .006 depends of the customers smarts or lack of

made the jig for harley cylinders for the machine to torque the base - then we made ( small platform from a small Bridgeport type machine ) for the Indian and assorted flat head jugs

today we do cast at .003 and some .0035 - hot rods forged .005 / .006 depends of the customers smarts or lack of

The following users liked this post:

TwiZted Biker (12-30-2022)

#64

We use a CK15 to do all the cylinders we had a CK10 before this one in the 80s - you put the length of the rod - the bore - and the stroke - what happens is the honing head starts and stops at the correct 60 degrees cross hatch while being flooded with honing oil as we watch the bore temps

made the jig for harley cylinders for the machine to torque the base - then we made ( small platform from a small Bridgeport type machine ) for the Indian and assorted flat head jugs

today we do cast at .003 and some .0035 - hot rods forged .005 / .006 depends of the customers smarts or lack of

made the jig for harley cylinders for the machine to torque the base - then we made ( small platform from a small Bridgeport type machine ) for the Indian and assorted flat head jugs

today we do cast at .003 and some .0035 - hot rods forged .005 / .006 depends of the customers smarts or lack of

#65

We use a CK15 to do all the cylinders we had a CK10 before this one in the 80s - you put the length of the rod - the bore - and the stroke - what happens is the honing head starts and stops at the correct 60 degrees cross hatch while being flooded with honing oil as we watch the bore temps

made the jig for harley cylinders for the machine to torque the base - then we made ( small platform from a small Bridgeport type machine ) for the Indian and assorted flat head jugs

today we do cast at .003 and some .0035 - hot rods forged .005 / .006 depends of the customers smarts or lack of

made the jig for harley cylinders for the machine to torque the base - then we made ( small platform from a small Bridgeport type machine ) for the Indian and assorted flat head jugs

today we do cast at .003 and some .0035 - hot rods forged .005 / .006 depends of the customers smarts or lack of

Your clearances sound like they are for cast iron cylinders. The liner cast in aluminum can be set a little tighter. Bored Pan and Shovel cylinders back in the early 70s but don't remember the clearances.

#66

one of the super gas engines we had a plug electrode wire fall into the engine doing a burn out - this in the middle of the session caused me to pull the engine back into the CK-15 and re hone it we ended up with .010 piston to wall and ran the car 62 more passes and never seen any thing that told me it was a mistake

but .0035 piston wall on a engine that Mauled up i have been asked to look at - do i know why it did that no - but seen it way to many times - long rod engines are a different thing -

the books you buy today have info that is 30 / 40 plus years ago from the flathead ford era - no matter what the guy said

#67

#68

#69

The following 2 users liked this post by Max Headflow:

Schex (01-02-2023),

TwiZted Biker (01-01-2023)

#70

The following 2 users liked this post by johnjzjz:

Max Headflow (12-31-2022),

TheVanillaThrilla (01-02-2023)