116 blew, 107 rebuild

#1

Almost 2 months ago, my 2000 FXDX threw a rod an busted the engine cases, crank, cylinders and pistons. The valves in the rear head may be tweaked.

Pics of the damage are located here.

https://www.hdforums.com/forum/twin-...-oil-leak.html

I figure to document the rebuild here for the heck of it. I'll mention that I'm not a professional, strictly an armature. I was a MC mechanic years ago but most of my current experience is putzing around with my own bikes. I bought the bike in this rebuild new back in November of 99. All the work to the bike has been done by me except for the paint, I hate paint. ;D It's been an 88ci stage 1, 95 ci stage 4, and 2 versions of a 116 (4 bore x 4 5/8 stroke). It became a 116 at 22000 miles and blew up a 64000+.

Last build.

116 ci, SnS 5 piece (early) flywheels, SnS 4 inch bore cylinders and pistons, 10 over

Delkron heads ported and flowed with AVnV valves. Heads milled to 83cc (originally 90cc)

SnS625 gear cams

CR set to 11.3 to 1

SnS G sand cast intake manifold with 1.8 ports, bored 2 1/4 on the intake (D size).

Custom CV51 manifold adapter.

CV51 with minor tweaks.

SnS tuned flow intake (the 1 with 2 forward facing KnN filters.)

Bassani RR exhaust.

DTT ignition.

Fueling oil pump.

Delkron cam plate.

That time on the dyno it made 125/128 with a G carb. The CV51 seemed to make more after adding the aircleaner as the clutch started to slip in the upper RPM ranges but it really hasn't been on the dyno since the G carb build.

Since I still have the stock 2000 crank with 22K, the plan is to rebuild it as a 4 1/8 bore x 4 inch stroke 107. With Wiseco 3.5cc pistons the CR will be about 11 to 1. I know the cranks was going but expected the flywheels to spread and oil pump die.. Was going to build the bike into a 117 but going 107 will save me the price of the crank.

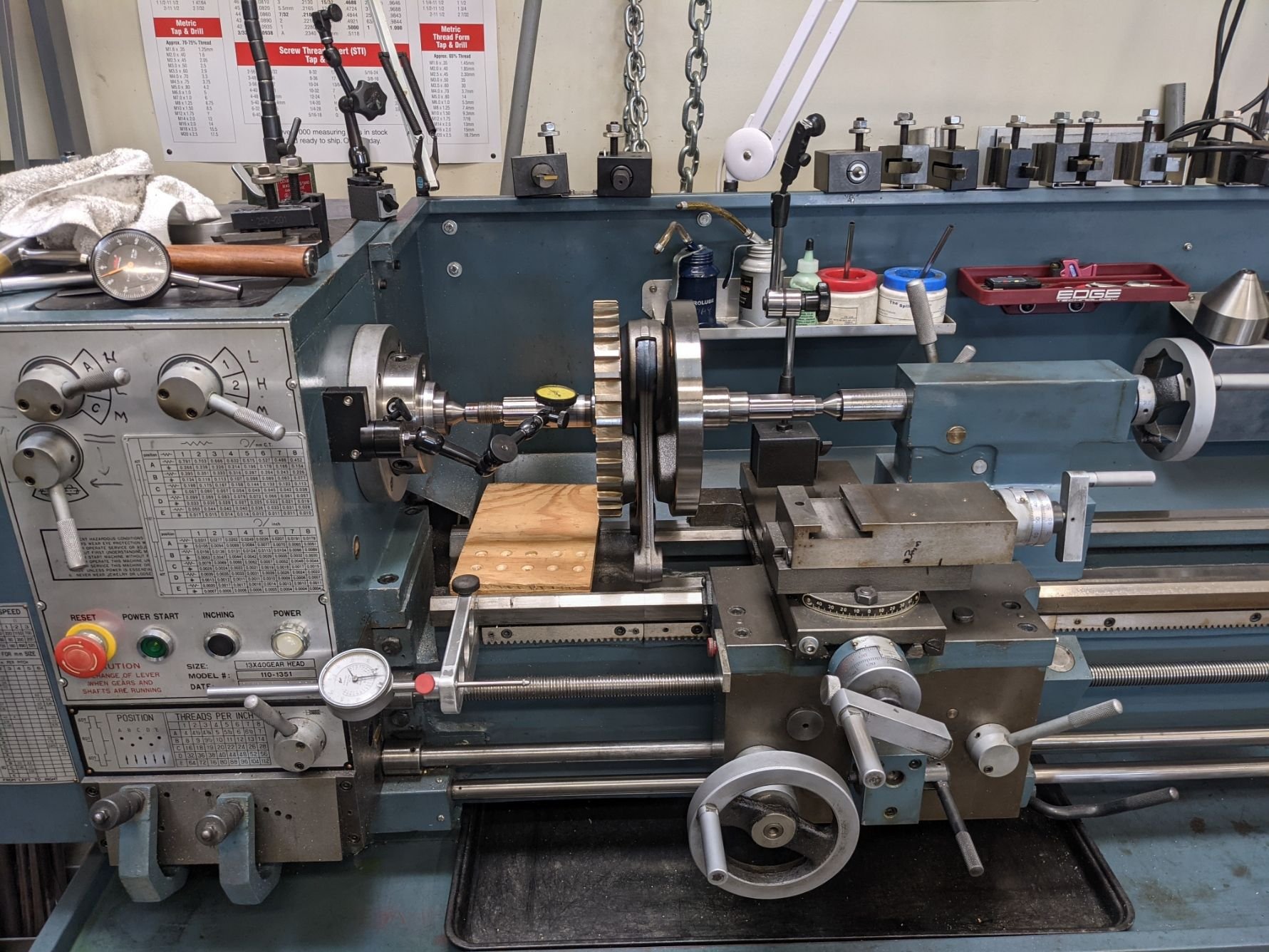

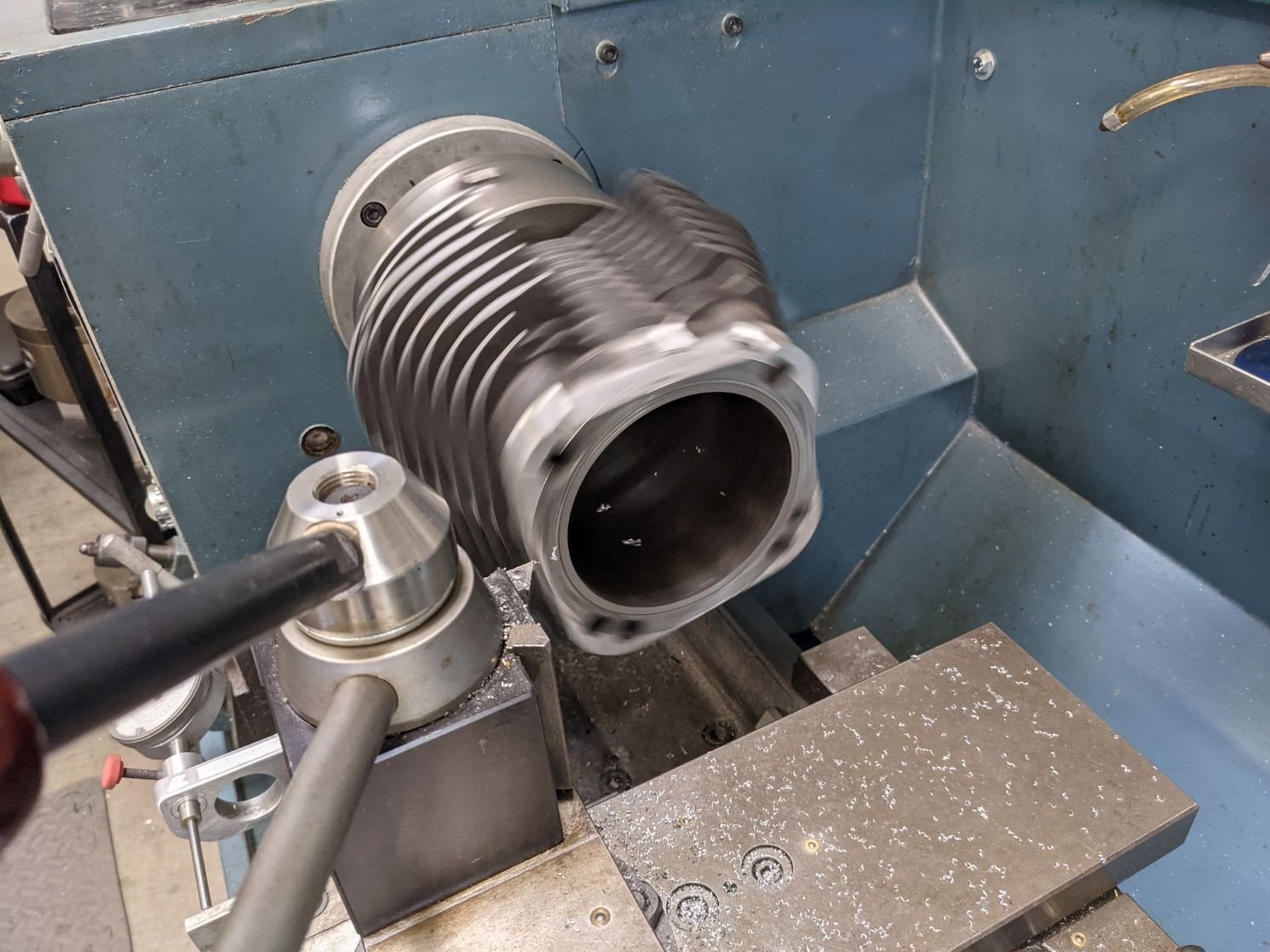

I can sleeve and bore the cylinders myself (I hope ) so total rebuild cost should be about $1200 to $1500. Engine cases were about $600 and Pistons $330. I need sleeves and misc. gaskets and bearings. I already have a lot of stuff .

) so total rebuild cost should be about $1200 to $1500. Engine cases were about $600 and Pistons $330. I need sleeves and misc. gaskets and bearings. I already have a lot of stuff .

I'm thinking to keep the 625 in there but may go to a Woods 9B.

Btw The motor locked up so quick that nothing got sucked into the oil pump. Cam case was also clean.

I'll be posting some pics.

Pics of the damage are located here.

https://www.hdforums.com/forum/twin-...-oil-leak.html

I figure to document the rebuild here for the heck of it. I'll mention that I'm not a professional, strictly an armature. I was a MC mechanic years ago but most of my current experience is putzing around with my own bikes. I bought the bike in this rebuild new back in November of 99. All the work to the bike has been done by me except for the paint, I hate paint. ;D It's been an 88ci stage 1, 95 ci stage 4, and 2 versions of a 116 (4 bore x 4 5/8 stroke). It became a 116 at 22000 miles and blew up a 64000+.

Last build.

116 ci, SnS 5 piece (early) flywheels, SnS 4 inch bore cylinders and pistons, 10 over

Delkron heads ported and flowed with AVnV valves. Heads milled to 83cc (originally 90cc)

SnS625 gear cams

CR set to 11.3 to 1

SnS G sand cast intake manifold with 1.8 ports, bored 2 1/4 on the intake (D size).

Custom CV51 manifold adapter.

CV51 with minor tweaks.

SnS tuned flow intake (the 1 with 2 forward facing KnN filters.)

Bassani RR exhaust.

DTT ignition.

Fueling oil pump.

Delkron cam plate.

That time on the dyno it made 125/128 with a G carb. The CV51 seemed to make more after adding the aircleaner as the clutch started to slip in the upper RPM ranges but it really hasn't been on the dyno since the G carb build.

Since I still have the stock 2000 crank with 22K, the plan is to rebuild it as a 4 1/8 bore x 4 inch stroke 107. With Wiseco 3.5cc pistons the CR will be about 11 to 1. I know the cranks was going but expected the flywheels to spread and oil pump die.. Was going to build the bike into a 117 but going 107 will save me the price of the crank.

I can sleeve and bore the cylinders myself (I hope

) so total rebuild cost should be about $1200 to $1500. Engine cases were about $600 and Pistons $330. I need sleeves and misc. gaskets and bearings. I already have a lot of stuff .

) so total rebuild cost should be about $1200 to $1500. Engine cases were about $600 and Pistons $330. I need sleeves and misc. gaskets and bearings. I already have a lot of stuff . I'm thinking to keep the 625 in there but may go to a Woods 9B.

Btw The motor locked up so quick that nothing got sucked into the oil pump. Cam case was also clean.

I'll be posting some pics.

The following 4 users liked this post by Max Headflow:

#2

The following 4 users liked this post by Max Headflow:

2013_FLHTK (07-31-2021),

Garage Queen Rescue (07-31-2021),

Gearhead88 (02-15-2022),

misfitJason (07-31-2021)

#3

The following 8 users liked this post by Max Headflow:

blue flht (07-31-2021),

djl (07-31-2021),

Garage Queen Rescue (07-31-2021),

Gearhead88 (02-15-2022),

misfitJason (07-31-2021),

and 3 others liked this post.

#4

#5

#6

The crank is really considered a 00 since it was a 00 DX. The cranks will get pseudo balanced to the pistons. Not taking it a part. HD actually balanced that crank.. Not sure when they stopped. Runout was 0.0018" - spread.

#7

What is the difference in the piston/rings/pin weightt?

When I first built my all bore 107 with Axtell's "Mountain Motor Kit" I had issue with their cylinders; two tries, cylinders would not hold a true bore. Dorfman was working the heads and suggested I have the cylinders re-sleeved by a guy in Cali that had a reputation for being one of the best. Liner slipped in less then 500 miles. To his credit, Dorfman made it good since it was his idea and agreed to pay for a set of re-sleeved cylinders from MTC Engineering; problem solved. Ran the motor pretty hard and they were holding up fine8K miles later when I sold the bike. I miss that all bore 107; very torquey motor. Hooked up with the Twist Gear it was pretty quick for a bagger and surprised a few that lined up with me at a light.

Looking forward to the thread.

When I first built my all bore 107 with Axtell's "Mountain Motor Kit" I had issue with their cylinders; two tries, cylinders would not hold a true bore. Dorfman was working the heads and suggested I have the cylinders re-sleeved by a guy in Cali that had a reputation for being one of the best. Liner slipped in less then 500 miles. To his credit, Dorfman made it good since it was his idea and agreed to pay for a set of re-sleeved cylinders from MTC Engineering; problem solved. Ran the motor pretty hard and they were holding up fine8K miles later when I sold the bike. I miss that all bore 107; very torquey motor. Hooked up with the Twist Gear it was pretty quick for a bagger and surprised a few that lined up with me at a light.

Looking forward to the thread.

Trending Topics

#8

What is the difference in the piston/rings/pin weightt?

When I first built my all bore 107 with Axtell's "Mountain Motor Kit" I had issue with their cylinders; two tries, cylinders would not hold a true bore. Dorfman was working the heads and suggested I have the cylinders re-sleeved by a guy in Cali that had a reputation for being one of the best. Liner slipped in less then 500 miles. To his credit, Dorfman made it good since it was his idea and agreed to pay for a set of re-sleeved cylinders from MTC Engineering; problem solved. Ran the motor pretty hard and they were holding up fine8K miles later when I sold the bike. I miss that all bore 107; very torquey motor. Hooked up with the Twist Gear it was pretty quick for a bagger and surprised a few that lined up with me at a light.

Looking forward to the thread.

When I first built my all bore 107 with Axtell's "Mountain Motor Kit" I had issue with their cylinders; two tries, cylinders would not hold a true bore. Dorfman was working the heads and suggested I have the cylinders re-sleeved by a guy in Cali that had a reputation for being one of the best. Liner slipped in less then 500 miles. To his credit, Dorfman made it good since it was his idea and agreed to pay for a set of re-sleeved cylinders from MTC Engineering; problem solved. Ran the motor pretty hard and they were holding up fine8K miles later when I sold the bike. I miss that all bore 107; very torquey motor. Hooked up with the Twist Gear it was pretty quick for a bagger and surprised a few that lined up with me at a light.

Looking forward to the thread.

Don was a great help setting me up with the guy at Advanced sleeve. He told me that MTC used short sleeves which he didn't like but I wonder if MTC uses Advanced Sleeve and because your order was for a 4 inch stroke, that was all that was needed. Advanced also makes long sleeves for 124s.. I went short as I don't have to worry about aligning the sleeves when I drop them in.. On a 4 inch stroke that is all that is needed.

Did the sleeved cylinders that slipped on you have a lip at the top of the sleeve or were they straight sleeves? The advance sleeves are lipped. IMO they have to be. For 1 the straight sleeve would make up about 1/2 the gasket surface width near the cylinder stud holes. With a sleeve that has a lip, it's like 95%.

We'll see if I screw this up.

#9

The following users liked this post:

Gearhead88 (02-15-2022)

#10