One cylinder running much hotter than the other

#51

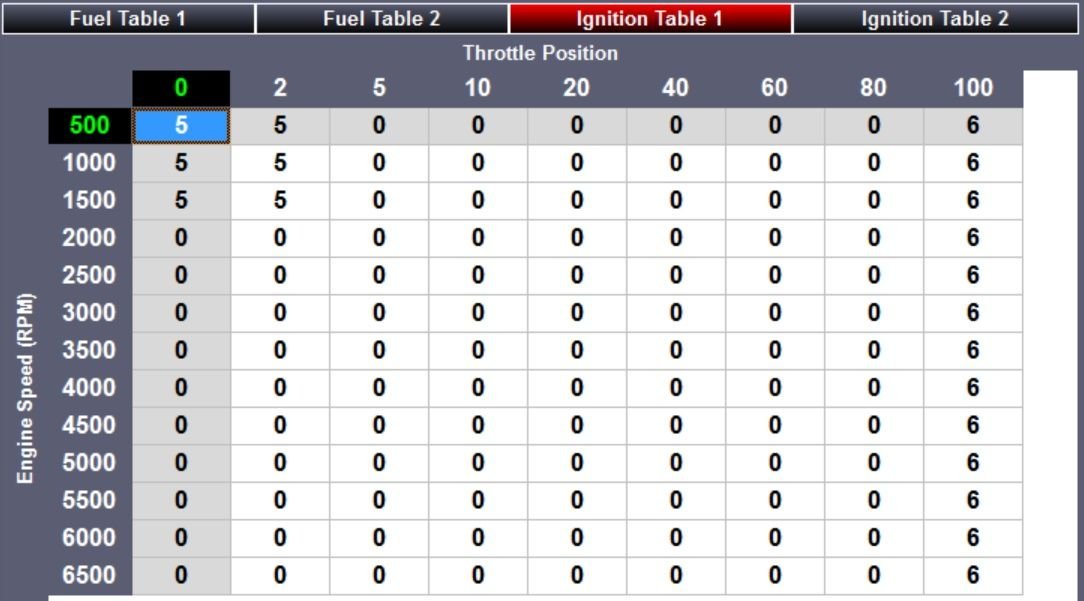

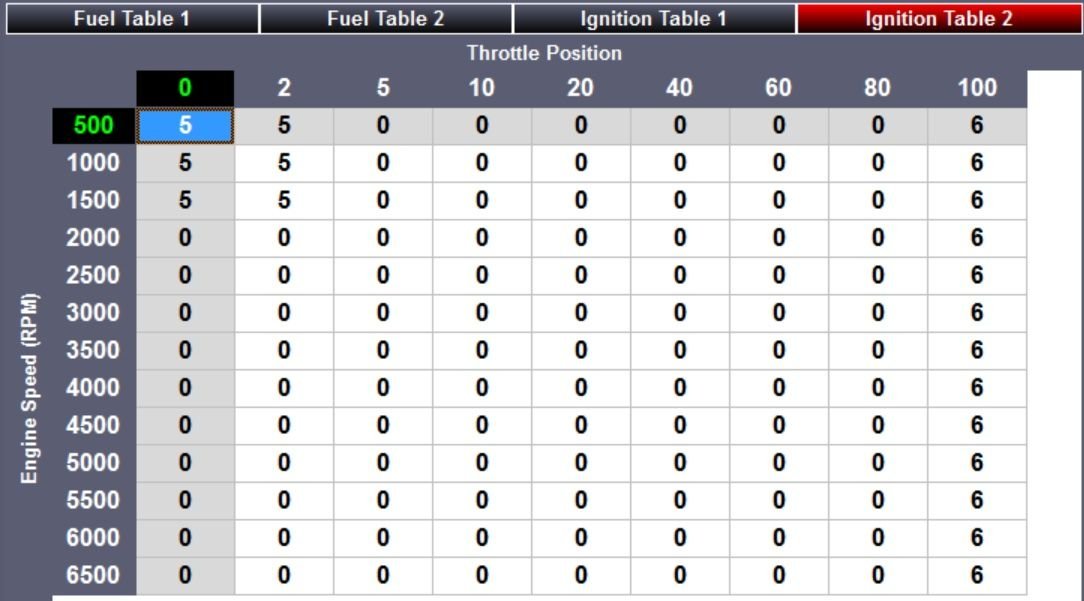

...you have posted up what looks like to me, a non advanced map with a single table figure out which tables are assigned to which actual cylinder on YOUR bike... you can make timing and fueling adjustments to JUST that cylinder and see if you can pin down why that one is running hotter, if it's fuel, igntion, or neither. if the fuel and the ignition are not making changes or positve progress, then pull the cylinder and inspect you oiling jet.

hope this helps.

m

hope this helps.

m

My a/f data logging setup is nearly complete. I wasn't able to finish this weekend but got close to it. Will be doing what you suggested and a bit more:

1. check a/f to see if rear is lean. If it is, look for cause in map and attempt to adjust. If no apparent cause found...

1a. swap injectors front to rear and see if problem follows the rear injector

2. tweak timing to determine impact on temps. If this and the above doesn't bring rear temp down enough, then...

3. inspect rear cylinder oil jet

Engine Break-In Procedure

Note: S&S engines are designed for high performance and as such are not as tolerant of inadequate break-in as stock or lower performance engines. Correct breakin will assure longer engine life and will prevent unnecessary engine damage. Engine damage caused by improper break-in is not covered under the S&S warranty.

A. Initial start up. Run engine approximately one minute at 1250-1750 rpm. DO NOT crack throttle or subject to any loads during this period as head gaskets are susceptible to failure at this time. During this time, check to see that oil pressure is normal, that oil is returning the oil tank, and that no leaks exist.

B. Shut off engine and thoroughly check for any leaks or other problems. Let engine cool to the touch.

C. After engine has cooled, start up again and allow the motor to build some heat. Engine should be run no longer than three to four minutes. When the cylinders become warm/ hot to the touch (approximately 150°) shut the motor down and let it cool to room temp. Follow the same cautions as for the initial start-up, and continue to watch for problems.

D. Repeat this procedure 3 or 4 times. Each successive time it should take slightly longer to warm up and you can increase the temp slightly each time (+10°). You can be more liberal each time with the rpm, gently vary rpm continuously from idle up to 2500 rpm in the final cycle. Don't be too concerned with final carb settings at this time because idle speed and mixture cannot be correctly set until the motor reaches full operating temperature. The motor should not reach that temperature during these cycles. Do not allow engine temperature to become excessive. After the motor has cooled to room temperature for the final time you are ready to start the 1000 mile engine break-in process.

E. The first 50 miles are most critical for new rings and piston break-in. Engine damage is most likely to occur during this period. Keep heat down by not exceeding 2500 rpm. Avoid lugging the motor, riding in hot weather or in traffic. Vary the engine speed. Do not lug the engine. We recommend changing the oil at 50 miles.

F. The next 500 miles should be spent running engine no faster than 3500 rpm or 60 mph. Avoid continuous steady speeds, and do not lug the engine. Vary engine rpm. We recommend changing the oil again at 500 miles.

CAUTION: Lugging or running engine prematurely at sustained high rpm may result in damage to pistons and other engine components. S&S voids it's guarantee if engine is not broken in properly.

================================================== =====

And the S & S take on dyno tuning, again from their website:

Dyno Break-In Procedure

- Follow the same procedure outlined above for initial start-up and heat cycling the engine.

- Run the bike for 25 miles on the dyno under varying speeds and loads while going up and down through the gears. Keep engine RPM below

3,500 RPM but do not lug the engine. The dyno must be operated so the engine runs under a load roughly equal to the power needed to move

the bike down the road, this would be about 12 hp at 55 mph. Keep engine head temperatures below 200 °F at the temp sensor or surface of

the head. Stop and cool the engine if needed. - Allow the engine to cool down to room temperature

- Run the bike for 25 more miles (50 miles total) under varying speeds, loads, gears as before. Make sure there is some load on the engine.

Keep engine speed below 4,250 rpm but do not lug the engine. Limited short bursts of throttle can aid in ring seating. Keep engine head

temperatures below 225 °F at the temp sensor or surface of the head. - After the first 50 miles on the dyno, it is recommended the normal break-in schedule be followed under normal riding conditions on the street.

See Step 5 above.

I would start by pilling 6 degrees across the board. Any place the motor feels weak, add a little, any place where it feels too peppy or pings pull it back. Fresh motor, you may not get detonation until carbon forms on the piston. In the meantime you are overheating the motor.

This sounds like it could be part of your problem......maybe. I guess whats not coming across in my posts is the dyno can be a very powerful diagnostic tool. you can make changes and closely monitor the results with real data, not seat of the pants feel or trying to listen with the wind in your ears. Right now with you "street tuning" it you have to get back home to make a change. On a dyno if you make an adjustment and it isn't right you can shut it down right away and back out of it. The other thing is changes in the tune can be made and evaluated more quickly. You have already had a major catastrophe that could have been caused by the tune, trying to break the new parts on the same tune doesn't seem like a good idea to me. A few hours on the dyno adjusting the tune can provide you with a bunch of data and eliminate the possible tune issue. If the problem still persists the tune has been eliminated and then other possible causes can be investigated.

Thread

Thread Starter

Forum

Replies

Last Post