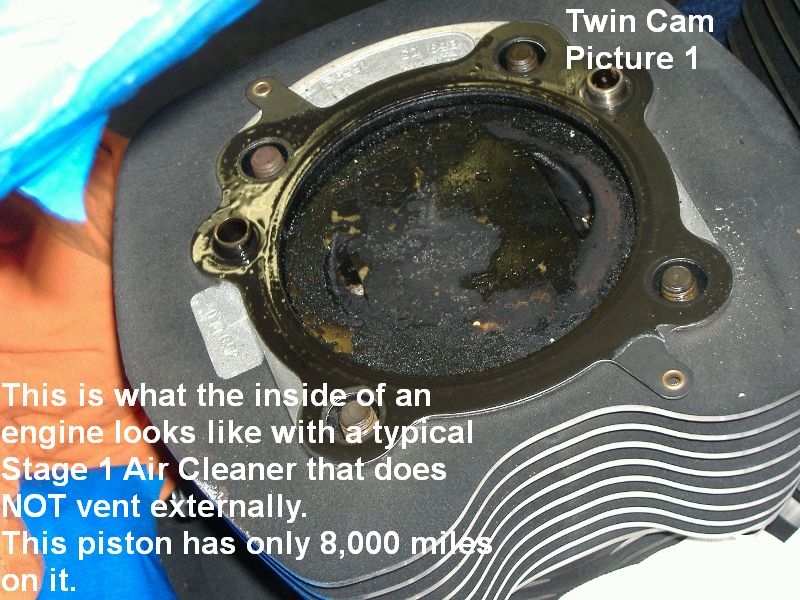

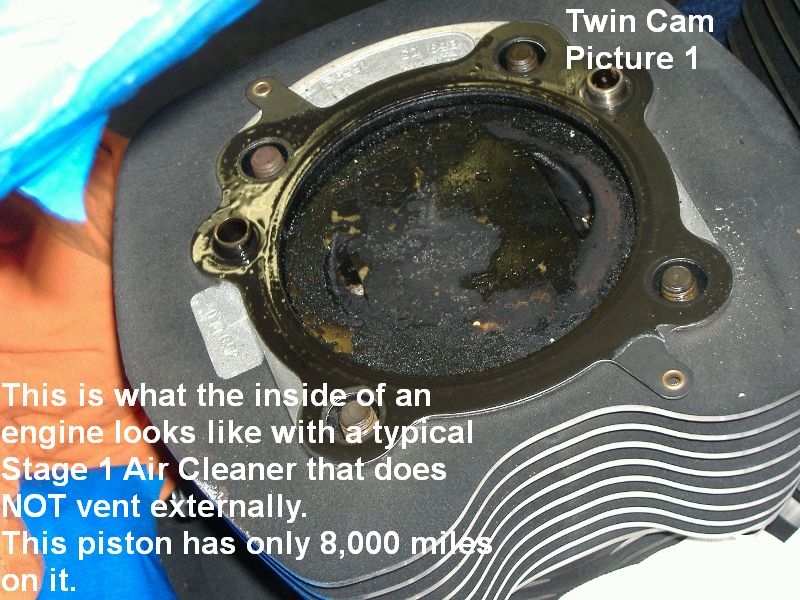

Piston/Head build up

#1

Replace the cams and decided to pull the heads and go with a .27 cometic head gasket. Was surprised with how much carbon crap builid up was on the piston. Any recomendations on how to clean it or should I just forget about it and move on?

I attribute this to the stupid breather tubes leading back into the AC. Need to do something about that, but have the SE Heavy breather so I would have to drill and plug it. agh Whoever comes up with this emissions crap is an idot. Likely make more engines run like crap vs blow out. Bike is a 2014 wg w/ roughly 3k miles. I was running the oil full but dropped that back to a reading of 1/2 way up the marker stick when cold, after the 1st oil change.

I attribute this to the stupid breather tubes leading back into the AC. Need to do something about that, but have the SE Heavy breather so I would have to drill and plug it. agh Whoever comes up with this emissions crap is an idot. Likely make more engines run like crap vs blow out. Bike is a 2014 wg w/ roughly 3k miles. I was running the oil full but dropped that back to a reading of 1/2 way up the marker stick when cold, after the 1st oil change.

#2

You can first try to dissolve the worst of it with carb cleaner. Don't drown it or some will leak past the rings into the crankcase. If you want completely clean piston tops, bring one piston to TDC, seal around the outside of the piston circumference with clean grease and cover the other. Use a wire brush on a grinder or drill to remove the carbon. Don't go overboard, just enough scrubbing to remove the carbon. Blow the residue off of the top of the piston with a leaf blower (not compressed air) and remove as much of the grease as possible from around the piston, then use the crank to move the piston all the way down in the bore and clean the bore and piston top thoroughly with brake cleaner on a clean, lint free cloth, again using it sparingly to avoid any getting past the rings into the crankcase. Continue wiping down the cylinder bore and piston top until the cloth picks up no residue and then wipe the bore with some clean motor oil. Now switch cylinders and repeat.

Combustion chambers on the heads can be cleaned using the wire brush/brake cleaner combo also.

Combustion chambers on the heads can be cleaned using the wire brush/brake cleaner combo also.

Last edited by dynawg1; 03-18-2015 at 09:03 AM.

#3

#4

#6

You could route externally by using a Hose Style Set Up. Then you would not have the worry of all the hot, dry, dirty, oily air getting back in.

Before routing externally.

After routing externally.

Hope this helps you out

Kelsey

Before routing externally.

After routing externally.

Hope this helps you out

Kelsey

__________________

Cristy

FREE SHIPPING - ORDERS OF $100 OR MORE - LOWER 48 STATES

www.DKCustom.com

Call: 662-252-8828

Text: 662-420-4891

Email: Support@DKCustomProducts.com

Cristy

FREE SHIPPING - ORDERS OF $100 OR MORE - LOWER 48 STATES

www.DKCustom.com

Call: 662-252-8828

Text: 662-420-4891

Email: Support@DKCustomProducts.com

#7

You can first try to dissolve the worst of it with carb cleaner. Don't drown it or some will leak past the rings into the crankcase. If you want completely clean piston tops, bring one piston to TDC, seal around the outside of the piston circumference with clean grease and cover the other. Use a wire brush on a grinder or drill to remove the carbon. Don't go overboard, just enough scrubbing to remove the carbon. Blow the residue off of the top of the piston with a leaf blower (not compressed air) and remove as much of the grease as possible from around the piston, then use the crank to move the piston all the way down in the bore and clean the bore and piston top thoroughly with brake cleaner on a clean, lint free cloth, again using it sparingly to avoid any getting past the rings into the crankcase. Continue wiping down the cylinder bore and piston top until the cloth picks up no residue and then wipe the bore with some clean motor oil. Now switch cylinders and repeat.

Combustion chambers on the heads can be cleaned using the wire brush/brake cleaner combo also.

Combustion chambers on the heads can be cleaned using the wire brush/brake cleaner combo also.

Wire wheeling is effective but creates a better chance of carbon getting into the rings, finish your build reassemble the motor (naturally cleaning the mating surfaces) and use marvel mystery oil or sea foam and relocate your breather to atmosphere. Very effective....

IF its ok, Id likely run it in both gas and oil, then run it around a bit & drop the oil/filter again....

Trending Topics

#8

You could route externally by using a Hose Style Set Up. Then you would not have the worry of all the hot, dry, dirty, oily air getting back in.

Hope this helps you out

Kelsey

Hope this helps you out

Kelsey

#9

I have seen your kit, but I like the SE Heavy breather and as such it wont work (unless Im missing something). Certainly can modify it but will likely require drilling, tapping, & plugging. UNLESS you made a SEHB end cap that replaces the stock ones & include some high temp epoxy to plug the holes along w/all the lines etc. lol

Before bolting it all back together for the Seafoam treatment, I think I would modify dynawg1's method by using the grease to seal the piston to cylinder gap and soak a sponge in Seafoam and let it sit on top of the carboned piston top for 24 hours. The Seafoam should loosen the crud so that you may be able to scrape it off with a plastic razor blade/scraper. Whatever crud you can't blow off with low pressure compressed air should be captured by the grease seal and can be cleaned up when the piston is dropped down in the cylinder. Be sure that when you apply the grease seal, you make sure the grease fills the top ring land gap; the gap between the top of the top ring and the top of the piston. I have never tried this but don't see why it won't work and am planning to take this approach when I pull the heads off my 95" late this year to upgrade the BigBoyz heads and replace the 44G cams with some TMan 590s.

BTW, if you haven't secured the cylinders to the cases yet, you need to do that ASAP to try and maintain the integrity of the cylinder to case seal at the base oring.

#10

It will work with the SE Heavy breather but, as you rightly point out, will require some drilling/tapping, etc.

Before bolting it all back together for the Seafoam treatment, I think I would modify dynawg1's method by using the grease to seal the piston to cylinder gap and soak a sponge in Seafoam and let it sit on top of the carboned piston top for 24 hours. The Seafoam should loosen the crud so that you may be able to scrape it off with a plastic razor blade/scraper. Whatever crud you can't blow off with low pressure compressed air should be captured by the grease seal and can be cleaned up when the piston is dropped down in the cylinder. Be sure that when you apply the grease seal, you make sure the grease fills the top ring land gap; the gap between the top of the top ring and the top of the piston. I have never tried this but don't see why it won't work and am planning to take this approach when I pull the heads off my 95" late this year to upgrade the BigBoyz heads and replace the 44G cams with some TMan 590s.

BTW, if you haven't secured the cylinders to the cases yet, you need to do that ASAP to try and maintain the integrity of the cylinder to case seal at the base oring.

Before bolting it all back together for the Seafoam treatment, I think I would modify dynawg1's method by using the grease to seal the piston to cylinder gap and soak a sponge in Seafoam and let it sit on top of the carboned piston top for 24 hours. The Seafoam should loosen the crud so that you may be able to scrape it off with a plastic razor blade/scraper. Whatever crud you can't blow off with low pressure compressed air should be captured by the grease seal and can be cleaned up when the piston is dropped down in the cylinder. Be sure that when you apply the grease seal, you make sure the grease fills the top ring land gap; the gap between the top of the top ring and the top of the piston. I have never tried this but don't see why it won't work and am planning to take this approach when I pull the heads off my 95" late this year to upgrade the BigBoyz heads and replace the 44G cams with some TMan 590s.

BTW, if you haven't secured the cylinders to the cases yet, you need to do that ASAP to try and maintain the integrity of the cylinder to case seal at the base oring.

Um... ****, Thanks, SOB threw on some plastic washers and used some large sockets as a temporaty solution. Figgured with how baked on the rest of the gaskets have been wouldnt have an issue with the base comming up.

OK so yes they did sit down just a bit... IDK a 1/16 F*^K

I was going to put it all back to gether tomorrow & Saturday... aghhhh

Any experience with such a situation and putting it back together w/out replacming them at this point?