Best set up for polishing aluminum?

#11

.

.

.

lotsa good advice here already.

polishing with a power tool can get real messy real fast.

I remove my aluminum for buffing with white and grey rouge.

final polish and upkeep I use a product called X-TREEM

.

.

.

.

.

.

.

.

.

.

for scratches, nicks, dings, I use diamond pads with water lube (red green black below)

or wet dry sandpaper of various grades

or even sometimes resort to a file.

.

.

.

.

.

.

.

.

.

.

.

.

fork lowers from seven years ago. TOMMAY's technique..........

.

.

.

.

.

lotsa good advice here already.

polishing with a power tool can get real messy real fast.

I remove my aluminum for buffing with white and grey rouge.

final polish and upkeep I use a product called X-TREEM

.

.

.

.

.

.

.

.

.

.

for scratches, nicks, dings, I use diamond pads with water lube (red green black below)

or wet dry sandpaper of various grades

or even sometimes resort to a file.

.

.

.

.

.

.

.

.

.

.

.

.

fork lowers from seven years ago. TOMMAY's technique..........

.

.

.

#14

.

.

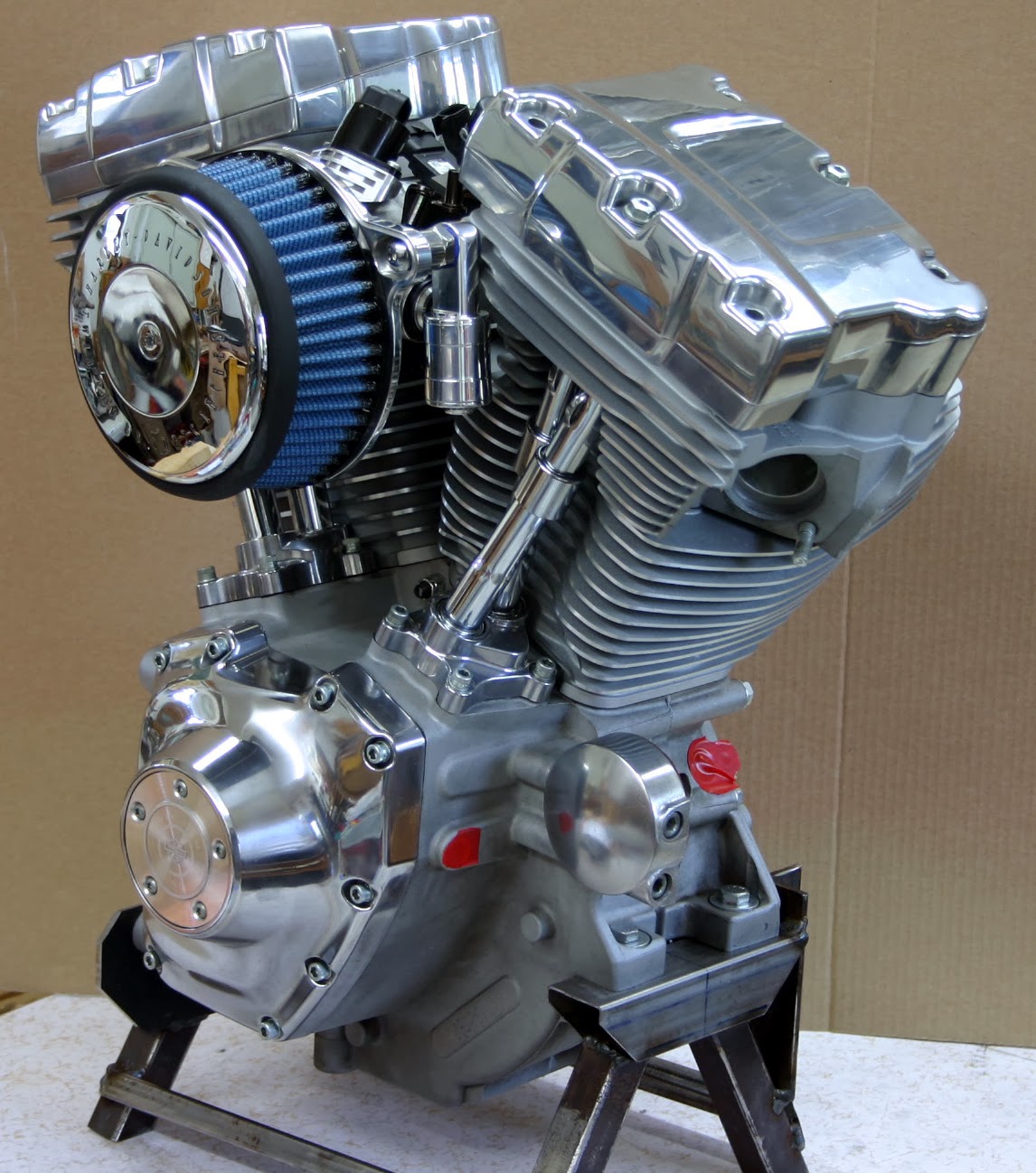

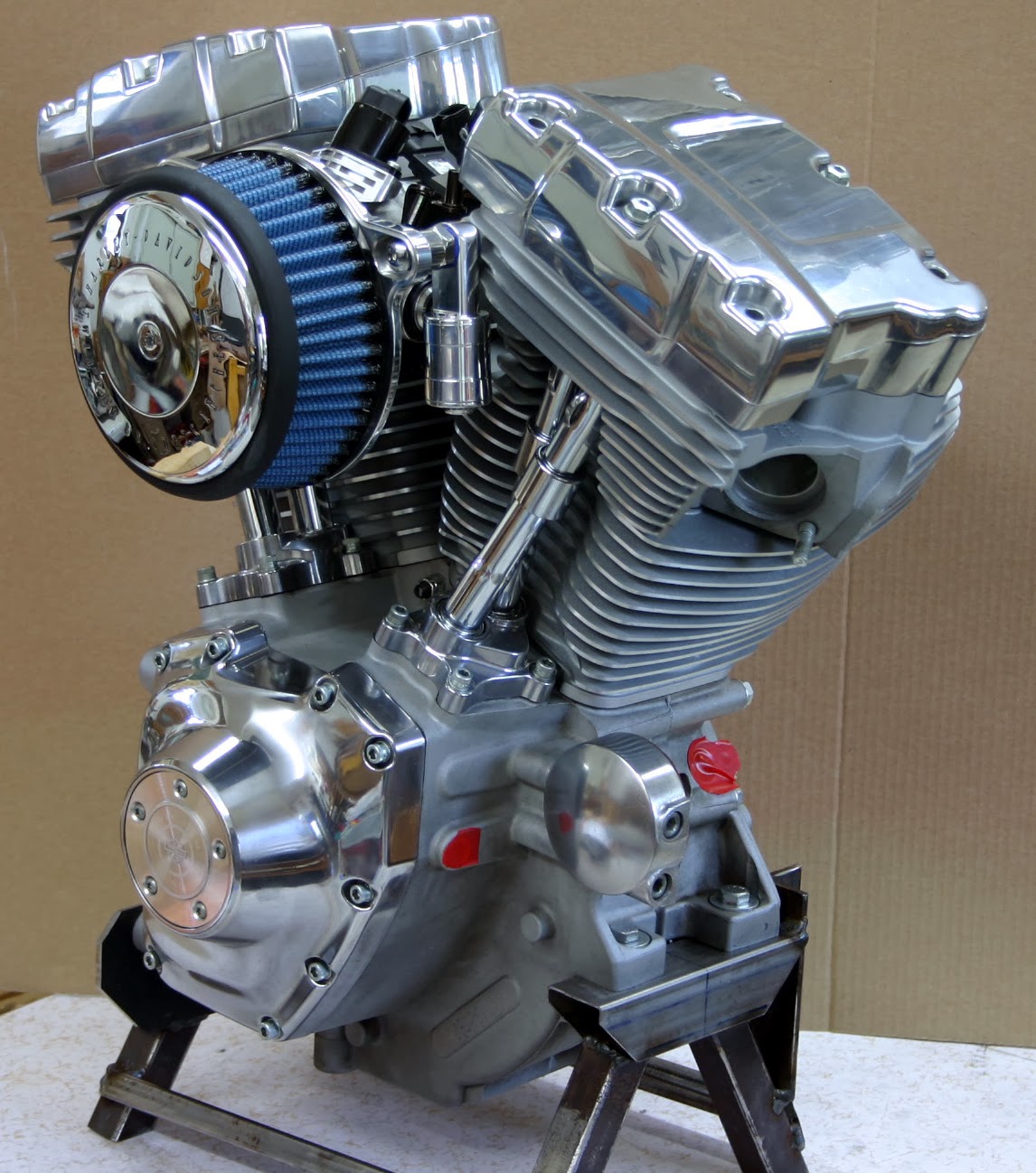

yessir. stripped all the powdercoating then polished.

polished aluminum is far more desirable to me than chrome.

I can't post the pix of the final wipe down..........

.

.

.

.

.

yessir. time and money is all it takes.

way cheaper to do it all yourownself though.

looks as if you are in Massachoochoo.

that gives you plenty of time to gitter done. 88F today here in South Texas.

tShirt ridin and I was sweating.

another pic of the primary cover etc............

.

.

.

.

.

#15

Join Date: Jul 2007

Location: sand mountain Alabama

Posts: 4,749

Likes: 0

Received 15 Likes

on

14 Posts

I may not know what mudd does but I have been polishing aluminum and stainless since the 70's.

With newer products and technology advancements It is a lot easier. A novice can have a almost professional look.

I have a simple jig I use to do wheels.

This simple jig will cut your time in half easy. I also use it when polishing. In this photo I am sanding to remove the milling and scratch marks out.

I use a hand held drill for wheels, a rigid with a 2 speed gear box that turns 3,000 rpms. A 8 inch wheel + a 3,000 rpm motor is the perfect speed for polishing. Cutting you pull the wheel against the direction of the motor, for polishing you move with the direction of the motor.

I start with brown, then white, then red compounds.

If sanding, depends on the condition of the wheel. If scratched I start with 360 geitt, if not much cleaning up is needed I will start with either 400 or 600, then 800, to 1,000 to 1,500 to 2,000 all wet sanded.

Hand rub, there is a lot of good choices out there so it's up to the user. I use mothers billet compound for hand finishing.

I prefer not to do the rocker boxes, I powder coat them because it is so difficult to clean.

Forks, they have a coating, I use fiber wheel or sissal wheels as some call them. They will remove the coating easy. Always always clean the wheel every 2 to 3 minutes. The metal build up, like you see in mudd's photo will cause serious damage. Scratches galore.

you can only get so much shine on metal. Some will look chrome like while some may just look real shiny. It's all in the metal. Foreign aluminum has so many degrees of what you can get. American is the best.

HD wheels are one of the best to polish. Jap stuff is a pain to get right.

With newer products and technology advancements It is a lot easier. A novice can have a almost professional look.

I have a simple jig I use to do wheels.

This simple jig will cut your time in half easy. I also use it when polishing. In this photo I am sanding to remove the milling and scratch marks out.

I use a hand held drill for wheels, a rigid with a 2 speed gear box that turns 3,000 rpms. A 8 inch wheel + a 3,000 rpm motor is the perfect speed for polishing. Cutting you pull the wheel against the direction of the motor, for polishing you move with the direction of the motor.

I start with brown, then white, then red compounds.

If sanding, depends on the condition of the wheel. If scratched I start with 360 geitt, if not much cleaning up is needed I will start with either 400 or 600, then 800, to 1,000 to 1,500 to 2,000 all wet sanded.

Hand rub, there is a lot of good choices out there so it's up to the user. I use mothers billet compound for hand finishing.

I prefer not to do the rocker boxes, I powder coat them because it is so difficult to clean.

Forks, they have a coating, I use fiber wheel or sissal wheels as some call them. They will remove the coating easy. Always always clean the wheel every 2 to 3 minutes. The metal build up, like you see in mudd's photo will cause serious damage. Scratches galore.

you can only get so much shine on metal. Some will look chrome like while some may just look real shiny. It's all in the metal. Foreign aluminum has so many degrees of what you can get. American is the best.

HD wheels are one of the best to polish. Jap stuff is a pain to get right.

Last edited by dirtdobber; 12-03-2013 at 06:23 PM.

#17

thanks for the suggestions, I'm going to get started. I got some mothers alum and mag polish and it's working really well. The triple trees already look 100% better, spent about 15 minutes last night trying out that vs the white compound. The fork lowers I'm going to need to sand and the wheel has spots, so i think that's going to have to be sanded too.

#18

#19

Since I didn't see it mentioned, the grade of aluminum makes a big difference. 6061 will fairly easily polish up with almost a chrome look, 5052 will not without a lot more work.

When I fabricate parts that I know will be powder coated I use 5052 for that reason and the fact that it is quite a bit less expensive than 6061.

When I fabricate parts that I know will be powder coated I use 5052 for that reason and the fact that it is quite a bit less expensive than 6061.

#20

Since I didn't see it mentioned, the grade of aluminum makes a big difference. 6061 will fairly easily polish up with almost a chrome look, 5052 will not without a lot more work.

When I fabricate parts that I know will be powder coated I use 5052 for that reason and the fact that it is quite a bit less expensive than 6061.

When I fabricate parts that I know will be powder coated I use 5052 for that reason and the fact that it is quite a bit less expensive than 6061.