How do you disassemble this connector?

#1

I'm replacing my rear turn signals and instead of just cutting the wires and soldering/wrapping things back up I thought I'd take a whack at doing it the right way.

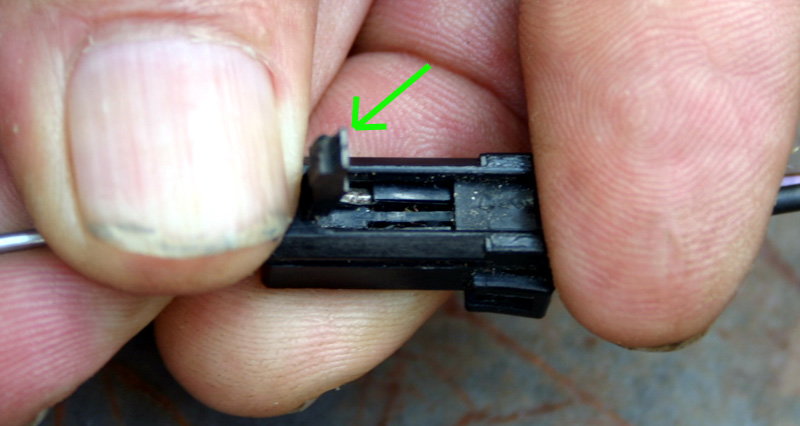

I should have cut the damn things as this little connector is driving me up the wall. The connectors below are the connectors at the end of your turn signal wires, which connect to a little electrical board behind the tail light housing.

I'm pretty sure there are a couple tabs in there that have to be pressed down in order to release the wire ends, but I can't see them, nor do I know where they really are inside the connector. I watched a vid that SC-Longhair did this past June where he took apart a Molex or Deusch (sp) connector of some sort but that really isn't the same thing I'm dealing with here.

Here are a few pics. If you know how to get the wires out of the connectors I'd appreciate some help. Thanks

Here's a view of the wires going in to the connector end:

Here's a view of the bottom of the connector; or the end that goes head first in to the electrical board:

Here's a side view to help you identify what I'm talkin' about:

I should have cut the damn things as this little connector is driving me up the wall. The connectors below are the connectors at the end of your turn signal wires, which connect to a little electrical board behind the tail light housing.

I'm pretty sure there are a couple tabs in there that have to be pressed down in order to release the wire ends, but I can't see them, nor do I know where they really are inside the connector. I watched a vid that SC-Longhair did this past June where he took apart a Molex or Deusch (sp) connector of some sort but that really isn't the same thing I'm dealing with here.

Here are a few pics. If you know how to get the wires out of the connectors I'd appreciate some help. Thanks

Here's a view of the wires going in to the connector end:

Here's a view of the bottom of the connector; or the end that goes head first in to the electrical board:

Here's a side view to help you identify what I'm talkin' about:

#2

I did a turn signal relocation on a friend of mine's Sportster and I think that I used a special pick tool that I got for my birthday. It was from Snap-on. There was a part number for the tool in the Harley service manual if I remember correctly. Even with the special tool, it was a PITA for sure. Good luck with your project and ride safe out there!

#3

#4

You have to go in from the plug side, above the pin itself. You can use a jewelers screwdriver or a stiff piece of wire about half the thickness of a metal coathanger.

You are trying to pry up a plastic tab that is holding the pin inside the connector. The tab is just below the tab that you squeeze to take the connector out of the plug in the taillight. You want to go in the plug against the pin and then swing towards the outside. In your second pic that would be from the top portion of the hole, against the pin and then swing towards the top or upward. It can be frustrating the first few times but it gets easy after doing several of them.

You are trying to pry up a plastic tab that is holding the pin inside the connector. The tab is just below the tab that you squeeze to take the connector out of the plug in the taillight. You want to go in the plug against the pin and then swing towards the outside. In your second pic that would be from the top portion of the hole, against the pin and then swing towards the top or upward. It can be frustrating the first few times but it gets easy after doing several of them.

Last edited by sniper77; 02-23-2010 at 05:08 AM.

#5

#6

I'm replacing my rear turn signals and instead of just cutting the wires and soldering/wrapping things back up I thought I'd take a whack at doing it the right way.

I should have cut the damn things as this little connector is driving me up the wall. The connectors below are the connectors at the end of your turn signal wires, which connect to a little electrical board behind the tail light housing.

I'm pretty sure there are a couple tabs in there that have to be pressed down in order to release the wire ends, but I can't see them, nor do I know where they really are inside the connector. I watched a vid that SC-Longhair did this past June where he took apart a Molex or Deusch (sp) connector of some sort but that really isn't the same thing I'm dealing with here.

Here are a few pics. If you know how to get the wires out of the connectors I'd appreciate some help. Thanks

Here's a view of the wires going in to the connector end:

Here's a view of the bottom of the connector; or the end that goes head first in to the electrical board:

Here's a side view to help you identify what I'm talkin' about:

I should have cut the damn things as this little connector is driving me up the wall. The connectors below are the connectors at the end of your turn signal wires, which connect to a little electrical board behind the tail light housing.

I'm pretty sure there are a couple tabs in there that have to be pressed down in order to release the wire ends, but I can't see them, nor do I know where they really are inside the connector. I watched a vid that SC-Longhair did this past June where he took apart a Molex or Deusch (sp) connector of some sort but that really isn't the same thing I'm dealing with here.

Here are a few pics. If you know how to get the wires out of the connectors I'd appreciate some help. Thanks

Here's a view of the wires going in to the connector end:

Here's a view of the bottom of the connector; or the end that goes head first in to the electrical board:

Here's a side view to help you identify what I'm talkin' about:

.

here ya go Bry..............

.

.

****AMP fitting release tool****

..

I've received several emails over the last three years asking about

extracting wires from the ever so popular AMP connectors.

HD uses these in several locations on their machines.

.

I am a strong believer in NOT cutting wires.

remove the lens, then unplug the fitting.

Really very simple to disassemble the electrical connectors

so you can pull the wires thru the standoffs.

I've heard quite a few folks on the forums

brag on how fast they can cut the wire and then solder.

Sadly, that bit of misinformation is a joke.

I can extract several before you can even get out

the snips, soldering gun, solder, shrink wrap, heat gun, etc.

Patience is a virtue while mastering this technique on the first wire.

After that, they get easier.

I can release them in a matter of seconds now.

Same is true for the other connectors that HD uses -

Deutsch, Packard, Delphi -

NO need to BUY SPECIAL extraction tools for any of these.

Here ya go:

Remove the two screws that hold the taillight to it's housing.

Use a small screwdriver to push the lock tab down a little,

and pull the fitting out.

.

.

.

This image below shows the 2 hole AMP and the tip of the 16 gauge wire I use.

Blue arrow shows a slight bend, and the tip is hammered flat.

Red is the first lock to undo. This is what holds the wires in the fitting.

Green is the tab that you released in the first step above,

it locks the fitting to it's receiver.

Green on the right is opened way up for some of the pix farther down.

Don't bend it out or you will ruin the fitting.

They are cheap, fifty cents or so.

.

.

.

Blue below, better shot of the 16 ga tip.

.

.

.

Next image you see I put an S bend in my release tool so I can control it better.

Also here you see that I have the turn indicator wire pushed fully IN

while raising the lock tang inside.

.

.

.

Now, below, once you have the lock tang lifted,

extract the wire.

.

.

.

Don't forget to pay attention to which wire comes from which side of the fitting.

There are small numbers on the housing.

In this case. 1 is purple, 2 is black.

Next two images illustrate where the tang is, and where the tip of my tool needs to be.

Green is pulled way up here simply for the photo.

.

.

.

I suggest buying a couple of new sockets so you can fold this way wide open

for your first try at this. If need be.

Little blue arrow indicates how far the end of the tang lifting wire needs to be.

.

.

.

These are great fittings, but, they are not watertight.

Green below shows a generous dab of dielectric compound on the tip of a little brush.

Red - the fitting is full

.

.

.

I made two video tutorials.............................

.

.

part 1 - http://www.youtube.com/embed/myPysAK2bWA

.

.

part 2 - http://www.youtube.com/embed/RNc0M74G4_Q

.

.

.

part 1 - http://www.youtube.com/embed/myPysAK2bWA

.

.

part 2 - http://www.youtube.com/embed/RNc0M74G4_Q

.

.

.

.

Last edited by mud; 02-02-2017 at 11:12 AM.

#9

I bought a glasses repair kit from the dollar store that has some small screw drivers.. i found the flathead in that kit to work the best for these connectors. i find them to be much smaller than your average precision screw driver.

*have to give credit to mud, it was the guidance of the above write up that i used to get it out.

*have to give credit to mud, it was the guidance of the above write up that i used to get it out.

The following users liked this post:

mud (02-04-2020)

#10

Thank you all so much, and especially you mud. That helps me tremendously. I'm going to pick up some additional connectors (now that I know the part # thanks to your photo). I'll bend the tab out of the way so i can see what I'm doing as you suggested.

Two lessons learned (possibly more to come):

1) Don't start taking **** apart at midnight when you only went into the garage for a smoke.

2) PATIENCE.

Two lessons learned (possibly more to come):

1) Don't start taking **** apart at midnight when you only went into the garage for a smoke.

2) PATIENCE.

The following users liked this post:

mud (02-04-2020)