Early TC Issues?

#51

Thanks for the reply back yeah I'm still on the fence would be nice to get it done all at once instead of doing it twice and I can't do the gear drive right now with out putting strain on my finances. If I can wait til winter I can tear it down and take my time and spend a little more and do it right. I did cut open my oil filter from last change and didn't find any orange pieces so that's good news will keep an eye on it next oil change.

Last edited by tcarson84; 05-20-2016 at 11:30 PM.

#52

Something I considered after reading all the articles is to add an oil pressure gage. The plastic from the tensioners doesn't seem to hurt the metal parts in the engine. The damage seems to come from them plugging the oil passages and jamming the cylinder nozzles open...so you lose oil pressure. With a gage I think you would see a change in the way the oil pressure behaves to alert you to a tensioner failure...or any other major engine problems.

I still want a pressure gage...but after spending on this I'll have to wait a few months to budget for it.

I still want a pressure gage...but after spending on this I'll have to wait a few months to budget for it.

#53

Good write up on your switch to gears.

Maybe I'm misunderstanding, but I hope you're not shifting & going WOT at only 1500-2000 RPMs. If so you'll be having bigger issues with your bottom end before too long. Only way I'd ever shift in that range is if I was coasting or shifting going down hill. I highly recommend shifting 2800-3000 RPM if you want your twin cam to last.

Are you sure the chain rattle wasn't actually pinging. 3000k miles the engine's not even hardly broke in.

Good lookin' bike BTW.

Maybe I'm misunderstanding, but I hope you're not shifting & going WOT at only 1500-2000 RPMs. If so you'll be having bigger issues with your bottom end before too long. Only way I'd ever shift in that range is if I was coasting or shifting going down hill. I highly recommend shifting 2800-3000 RPM if you want your twin cam to last.

Are you sure the chain rattle wasn't actually pinging. 3000k miles the engine's not even hardly broke in.

Good lookin' bike BTW.

#54

Put 500 miles on her today. Still purrs, no more cam racket and it's running great. In top gear it comes on the cam right at 70mph, so perfect for the highway here in Texas. Below 70 you have to remember to downshift...and then hold on!

I've got no complaints at all with the 510 and gears.

I've got no complaints at all with the 510 and gears.

#55

Put 500 miles on her today. Still purrs, no more cam racket and it's running great. In top gear it comes on the cam right at 70mph, so perfect for the highway here in Texas. Below 70 you have to remember to downshift...and then hold on!

I've got no complaints at all with the 510 and gears.

I've got no complaints at all with the 510 and gears.

#56

I've heard from many riders that my bike is prone to issues as the first year of the twin cam. I've been ignoring them. Today I road without a helmet and noticed a little clatter from the cam side...only between 1500 to 2000 RPM. Above and below it is silent (except for the obvious exhaust note). Might be time to pay attention. I searched for information in the tech section, but I think most bikes have been modified long before...so it's old news and I can't go back far enough to learn any details.

Can some old head fill me in on exactly what the issues with the first year TC's were...and what to look for/modify?

Can some old head fill me in on exactly what the issues with the first year TC's were...and what to look for/modify?

Did I miss the answer to this?

Last edited by Jackie Paper; 05-22-2016 at 08:36 AM.

#57

So the simple answer is S&S has taken care of it...you don't have to do anything.

#58

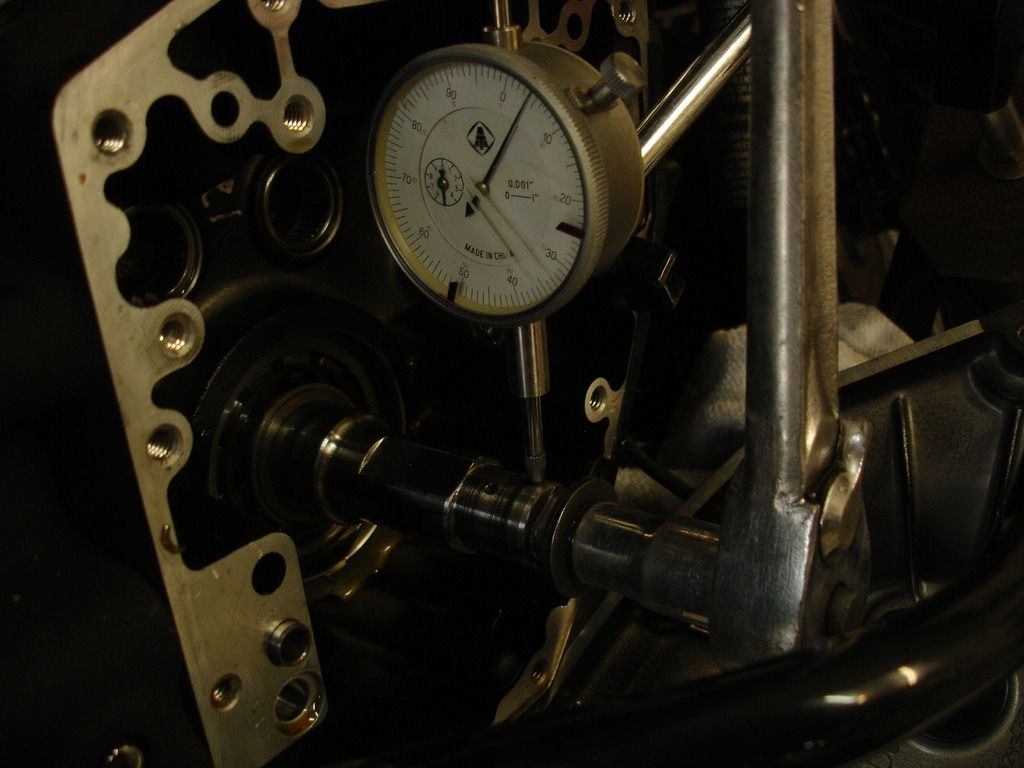

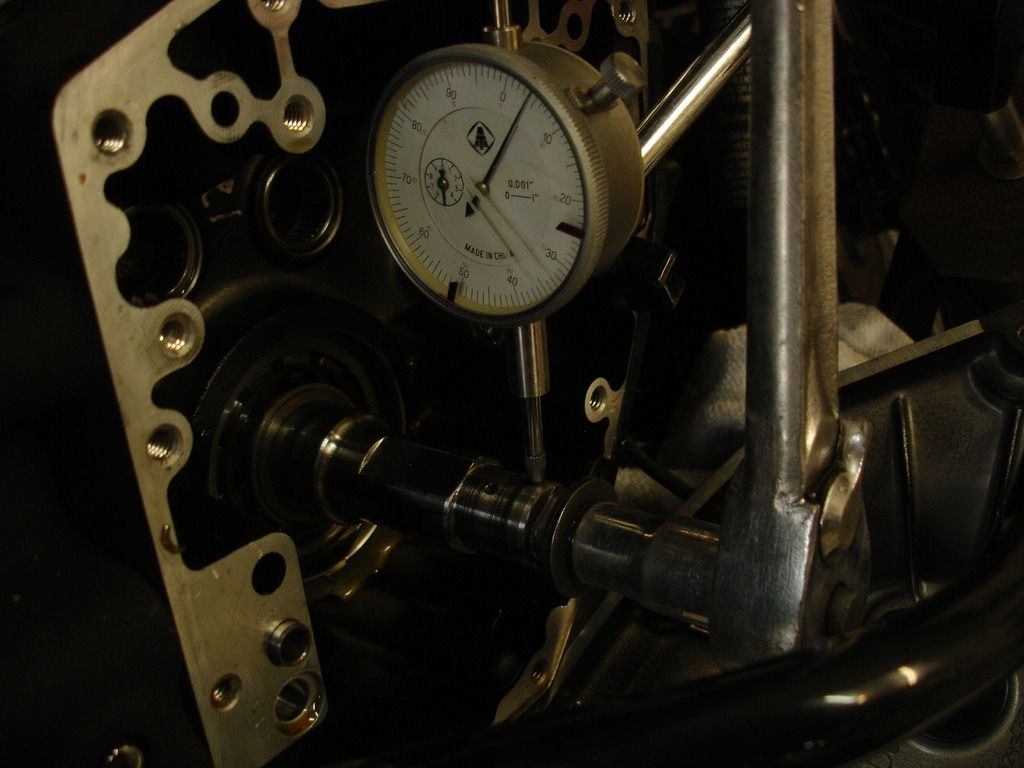

The Torringtons are a recommended upgrade for all TC's, all years. The original bearings are not overly weak...but the Torringtons are burly strong. I like that. So, at this point we need to check the crankshaft for twist. A little history:

The early cranks were forged (mine is in this '99 FXDX). Later cranks with larger displacements switched to cast cranks. Under heavy loads the flywheels can twist on the crank pin, right around the pressed fit pin. This is much more common on the newer bikes. If the crank has twisted, the snout that sticks out and drives the cams and oil pump will "wobble".

We will check the crank snout for wobble now.

Here is a cheapo dial indicator and base, set up to measure any wobble on the snout. I have installed a bolt into the crank and spin it with a wrench, while I measure the "runout". .003" is acceptable. Mine was .001", so I am good to continue the gear cam installation.

The old lady wants to go to lunch...I'll be back with the rest later...

The early cranks were forged (mine is in this '99 FXDX). Later cranks with larger displacements switched to cast cranks. Under heavy loads the flywheels can twist on the crank pin, right around the pressed fit pin. This is much more common on the newer bikes. If the crank has twisted, the snout that sticks out and drives the cams and oil pump will "wobble".

We will check the crank snout for wobble now.

Here is a cheapo dial indicator and base, set up to measure any wobble on the snout. I have installed a bolt into the crank and spin it with a wrench, while I measure the "runout". .003" is acceptable. Mine was .001", so I am good to continue the gear cam installation.

The old lady wants to go to lunch...I'll be back with the rest later...

With respect to crank runout, does the twisting of the flywheel on the crank cause excessive runout, or is the runout due to poor manufacturing? If caused by twisting, then I suppose it's possible that a crank could develop excessive runout in the future. Thoughts?

Thanks for taking to photo document this! Be interested to hear what you mpg is with the new cams.

#60

I suppose the runout could be caused by poor manufacturing, but I would hope that Harley keeps the tolerances pretty tight for new cranks. The allowable in the S&S instructions is .003". For us end users, the main thing to know is that if the crank does twist, it's easiest to check for it by checking the runout. If it runs with a lot of runout it will quickly chew up that bronze bushing you see in the cam plate. Once that wallows out, the oil pump is next to go, resulting in low oil pressure.

That's why an oil pressure gage is high on my upgrade list...the more I study up, it seems that most internal problems on our TC's can be caught early by looking for a change in the way the oil pressure behaves.

That's why an oil pressure gage is high on my upgrade list...the more I study up, it seems that most internal problems on our TC's can be caught early by looking for a change in the way the oil pressure behaves.