Early TC Issues?

#23

#24

#25

I talked to S&S this morning and ordered the 510G gear kit. That's the most cam the engine will take without changing the springs, and supposedly comes with everything needed to button up the cams and cover.

I will still need the upper seals and gaskets. I was going to go with the adjustable pushrods, but then realized that with the gears there is really no reason to ever open up the cam cover again, unless it's for something major that everything will have to come out anyway. So, with no need to inspect tensioners ever again, there is no real advantage to the adjustables.

The S&S tech said that they never see twisting issues with the '99-'02 cranks. I guess those were the forged, good units. Whereas, later Harley went to the cast assemblies that have twisting problems.

I'll post pics of the installation when the parts get here Wednesday. This should take care of any and all "early TC issues". Thanks again for all the info you guys provided!

I will still need the upper seals and gaskets. I was going to go with the adjustable pushrods, but then realized that with the gears there is really no reason to ever open up the cam cover again, unless it's for something major that everything will have to come out anyway. So, with no need to inspect tensioners ever again, there is no real advantage to the adjustables.

The S&S tech said that they never see twisting issues with the '99-'02 cranks. I guess those were the forged, good units. Whereas, later Harley went to the cast assemblies that have twisting problems.

I'll post pics of the installation when the parts get here Wednesday. This should take care of any and all "early TC issues". Thanks again for all the info you guys provided!

#27

OK, here comes a real treat for you gear heads. All you guys who farm your work out can move on to the next thread!

To recap where I have gone, I rode my '99 TC88 last week with no helmet, and heard all kind of racket coming from the cam side (right) of the engine. Thanks to you guys here on the forum, I studied and learned about the short comings of the early TC valve train.

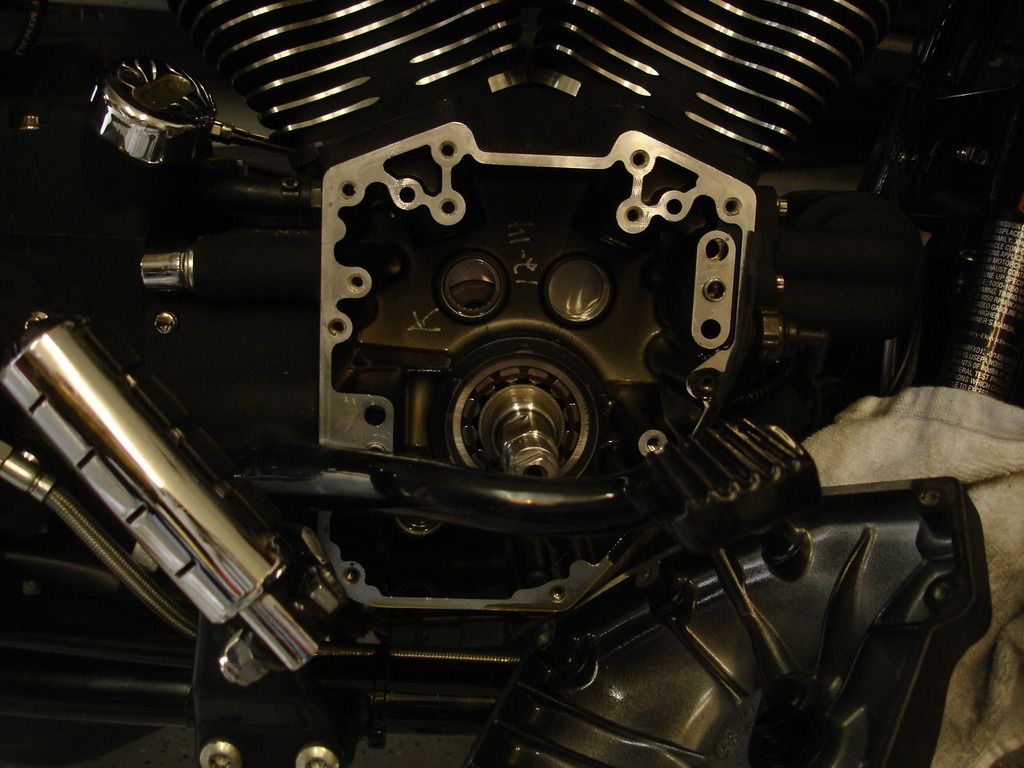

Well, not being able to leave well enough alone, I converted to a gear drive cam. I chose the S&S 510G, as the largest cam I can fit in the box without modifying the heads. So, now you get a tour of installing a gear drive in a TC. It is the same for just about any year TC, just some minor kit differences, but the install is identical.

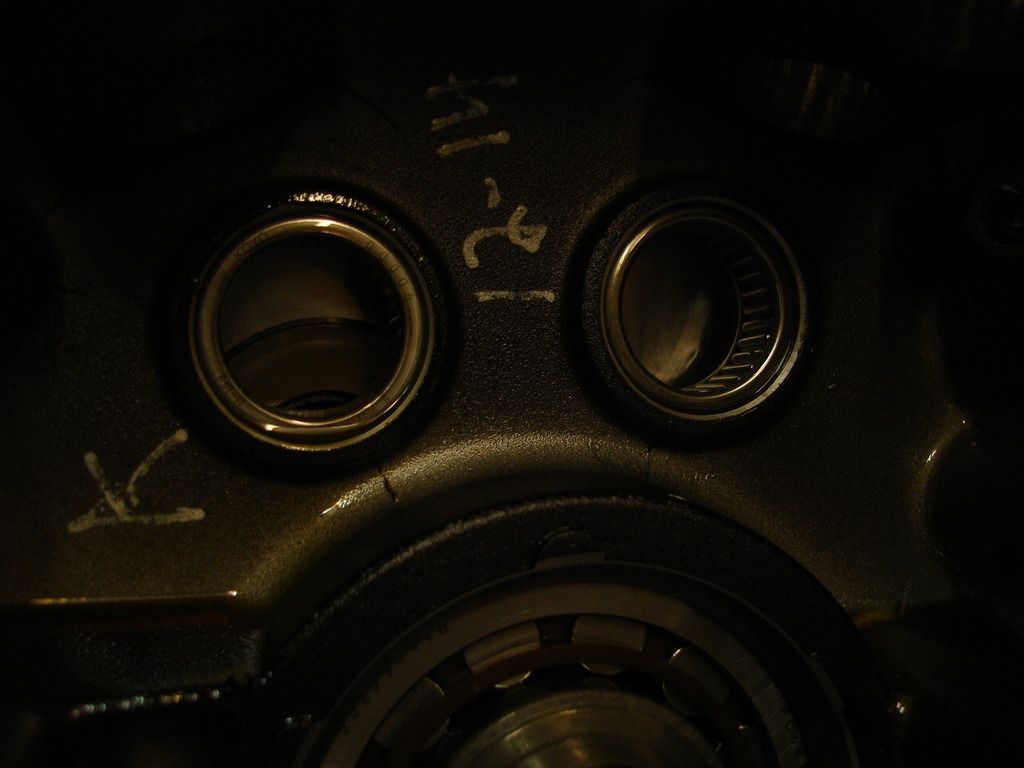

We start with the motor open and everything disassembled. So first to be installed are the Torrington B148 needle bearings into the web between the crankcase and the cam case. These shots are of the bearings that came out next to the Torrington going back in. The Torrington has double the rollers...and thus much higher load carrying ability.

To recap where I have gone, I rode my '99 TC88 last week with no helmet, and heard all kind of racket coming from the cam side (right) of the engine. Thanks to you guys here on the forum, I studied and learned about the short comings of the early TC valve train.

Well, not being able to leave well enough alone, I converted to a gear drive cam. I chose the S&S 510G, as the largest cam I can fit in the box without modifying the heads. So, now you get a tour of installing a gear drive in a TC. It is the same for just about any year TC, just some minor kit differences, but the install is identical.

We start with the motor open and everything disassembled. So first to be installed are the Torrington B148 needle bearings into the web between the crankcase and the cam case. These shots are of the bearings that came out next to the Torrington going back in. The Torrington has double the rollers...and thus much higher load carrying ability.

#28

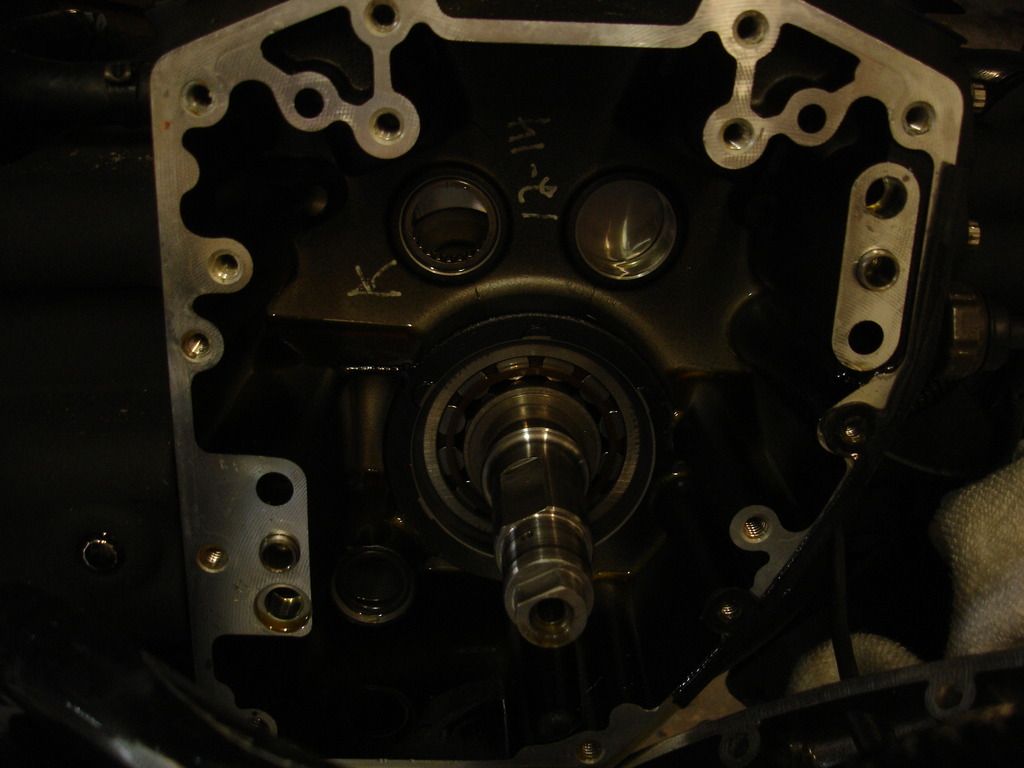

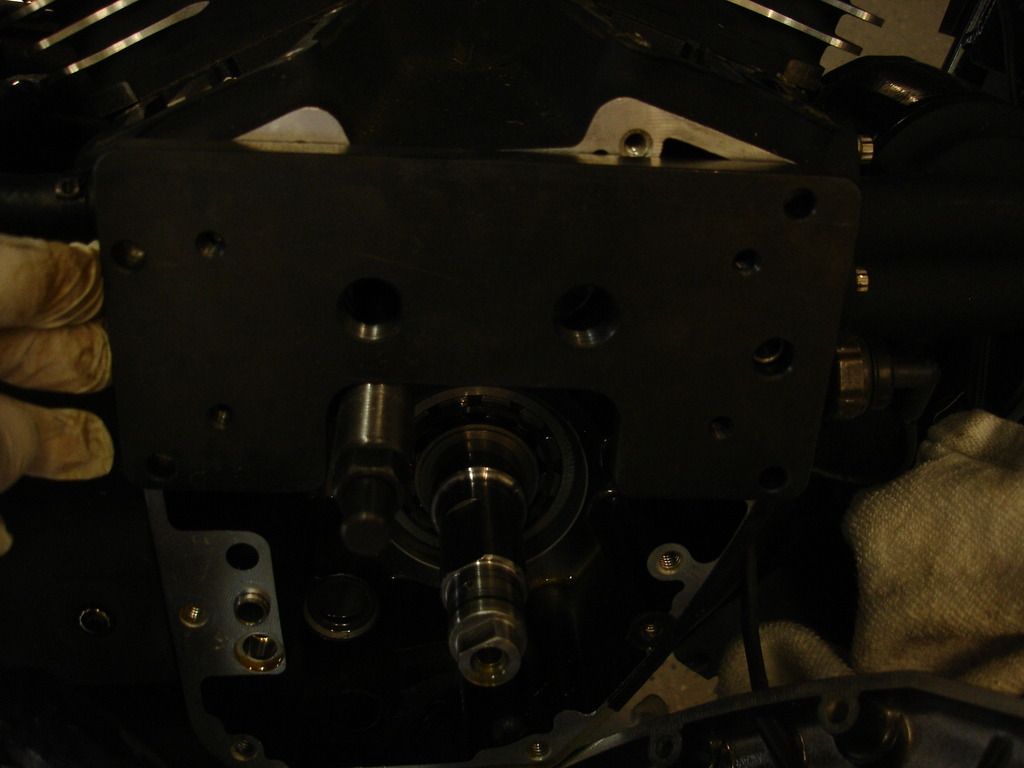

This is the empty case. The crank shaft is at the bottom. The 2 holes above are the inside bearing holes for the 2 cams. The ANI bearing has been removed from the right side, so now we will remove the other stock ANI from the left cam hole.

This is the needle bearing removal tool I got off Ebay for $80. We will use the tool set to both remove the old needles and install the new.

First the tool gets tapped into the old needle bearing, so it snaps in place, grabbing the back of the bearing.

This rod gets inserted inside the "claw" tool, to hold the fingers tightly outward, against the back of the bearing.

Now you lay the large tool plate against the case, install the nut and washer and tighten the nut. This pulls the bearing right out...no muss, no fuss.

Now we switch to these tools that came in the kit. These will be used to install the new Torringtons.

Set up like this. The bearing goes on the end of the installer.

Oiling the bearing for the installation.

Then the plate goes onto the case. This time we have to anchor the large tool plate using 4 nut screws that thread into the case cover screw holes.

Now we screw the long bolt into the tool plate, which is threaded. This pushes the new bearing right into place. You will feel it bottom. DO NOT force the bolt once you feel it bottom. The bolt is stronger than the aluminum case!

New bearings installed and ready to take the new cams.

#29

The Torringtons are a recommended upgrade for all TC's, all years. The original bearings are not overly weak...but the Torringtons are burly strong. I like that. So, at this point we need to check the crankshaft for twist. A little history:

The early cranks were forged (mine is in this '99 FXDX). Later cranks with larger displacements switched to cast cranks. Under heavy loads the flywheels can twist on the crank pin, right around the pressed fit pin. This is much more common on the newer bikes. If the crank has twisted, the snout that sticks out and drives the cams and oil pump will "wobble".

We will check the crank snout for wobble now.

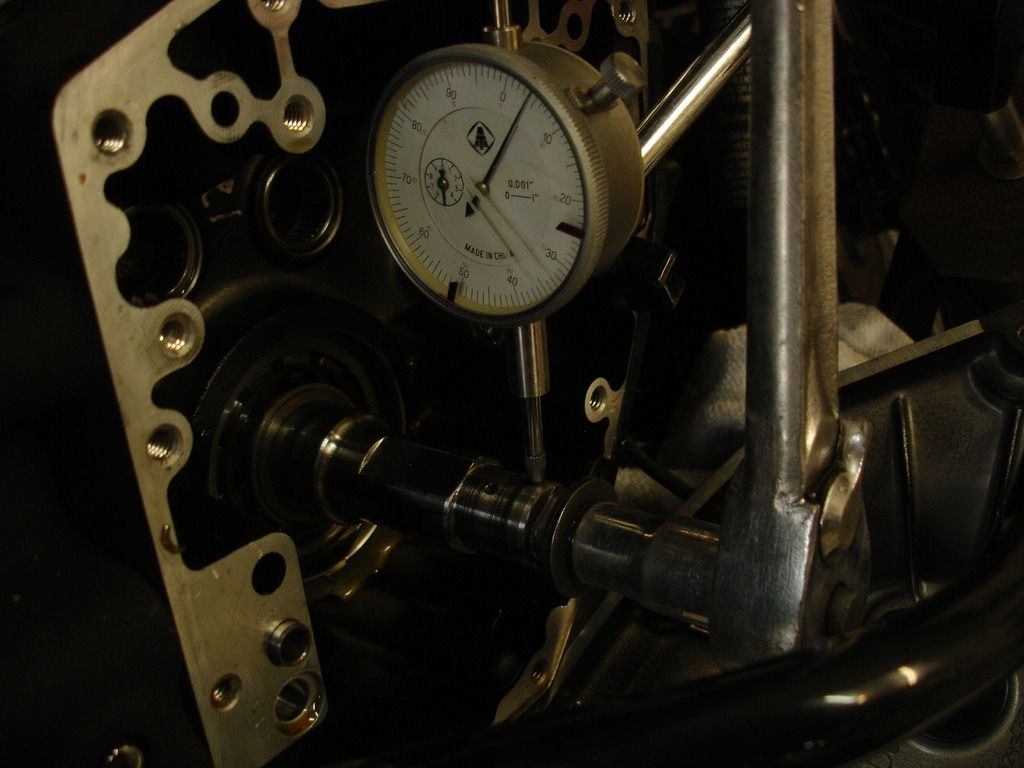

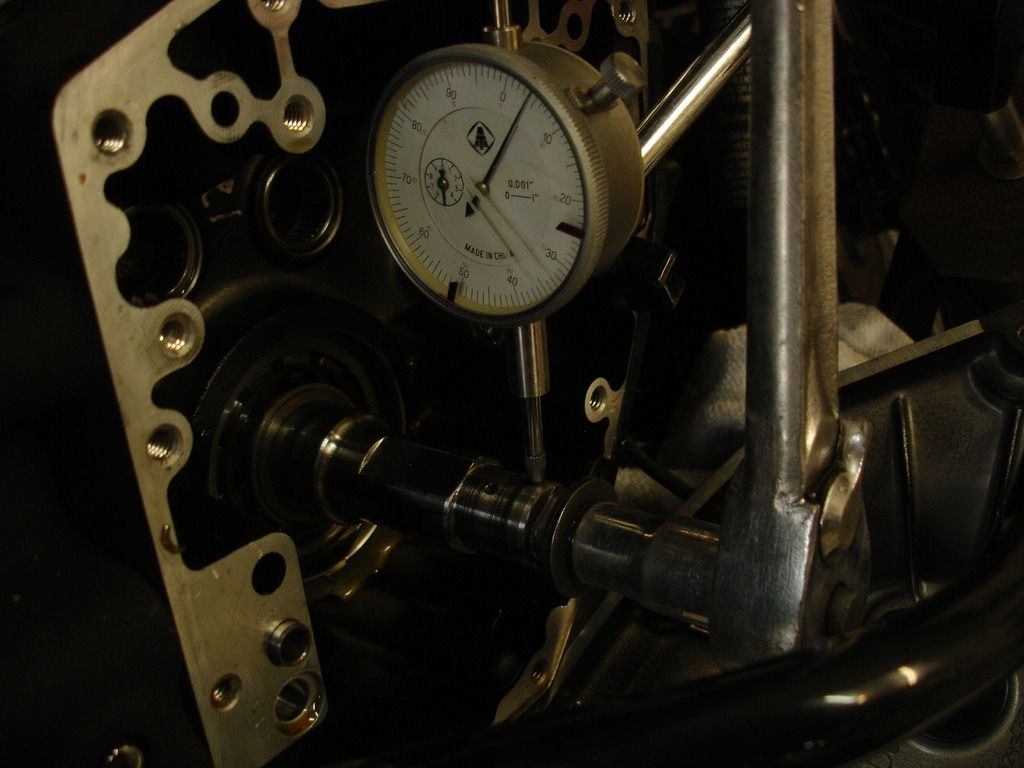

Here is a cheapo dial indicator and base, set up to measure any wobble on the snout. I have installed a bolt into the crank and spin it with a wrench, while I measure the "runout". .003" is acceptable. Mine was .001", so I am good to continue the gear cam installation.

The old lady wants to go to lunch...I'll be back with the rest later...

The early cranks were forged (mine is in this '99 FXDX). Later cranks with larger displacements switched to cast cranks. Under heavy loads the flywheels can twist on the crank pin, right around the pressed fit pin. This is much more common on the newer bikes. If the crank has twisted, the snout that sticks out and drives the cams and oil pump will "wobble".

We will check the crank snout for wobble now.

Here is a cheapo dial indicator and base, set up to measure any wobble on the snout. I have installed a bolt into the crank and spin it with a wrench, while I measure the "runout". .003" is acceptable. Mine was .001", so I am good to continue the gear cam installation.

The old lady wants to go to lunch...I'll be back with the rest later...

The following users liked this post:

1999 Wide Glide (05-20-2016)