124" winter build...

#162

I got the mainshaft seal and the trap door gasket on today. After that I was able to press the IPB race on the mainshaft. Heated it up a little in the oven at 250* for about 20 minutes. Oiled the **** out of it, the shaft and the tool and it went on without much fight. Book calls for it to be .100-.125 from the MDG, I think mine ended up around .117

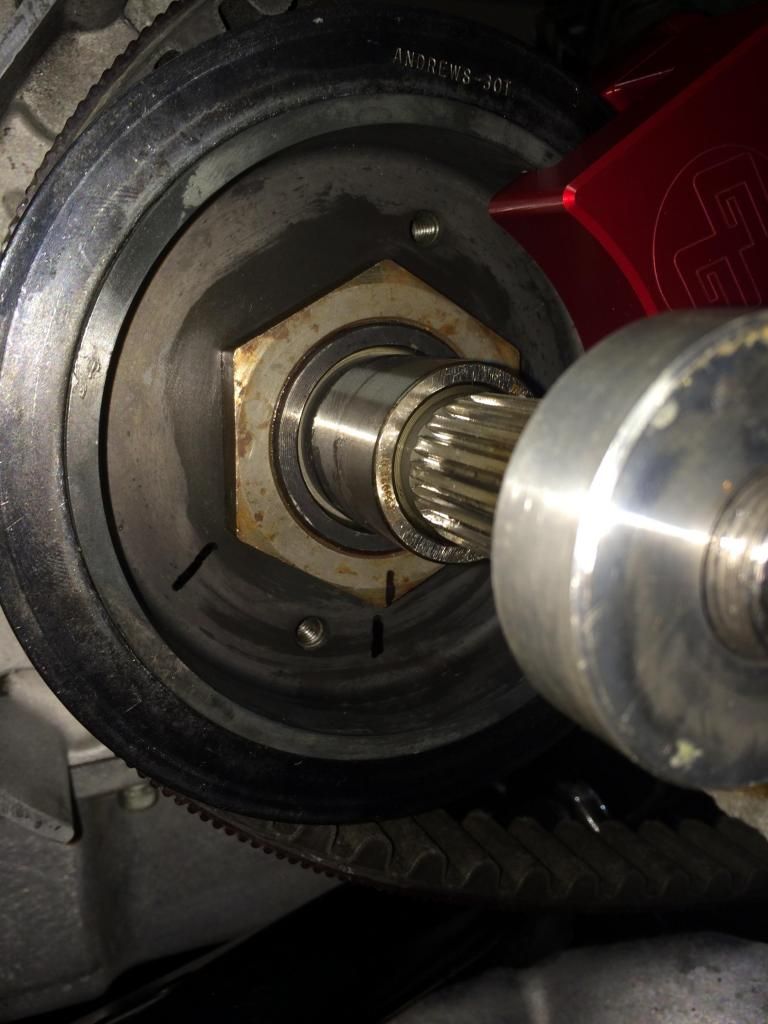

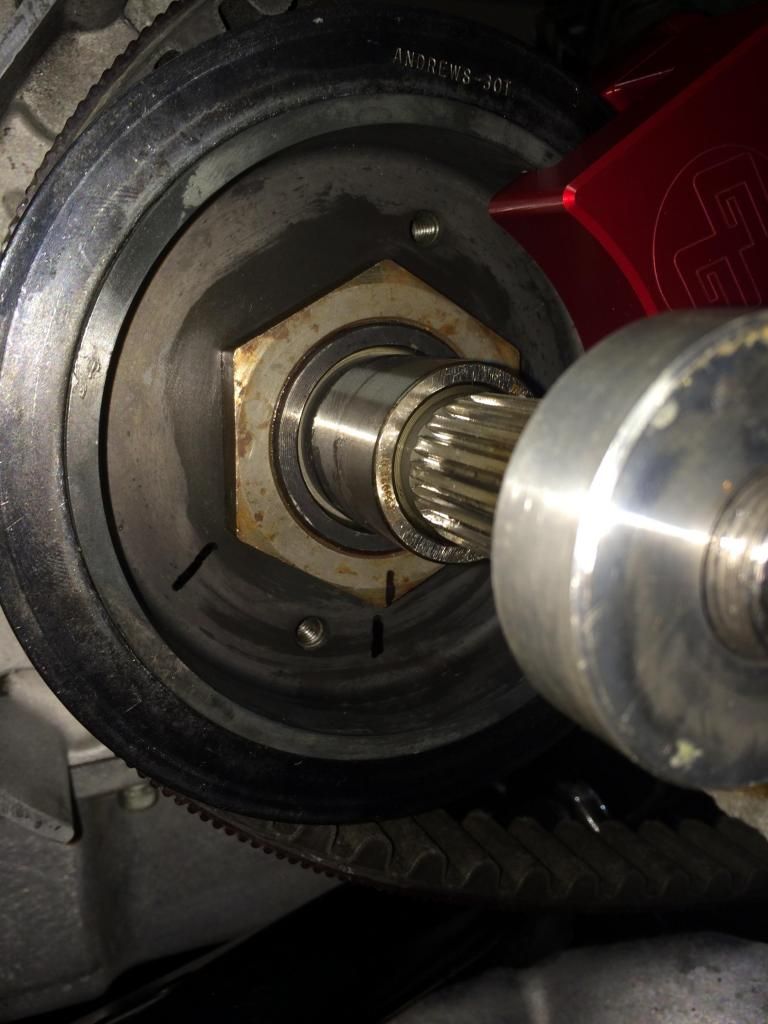

After that it was time for the sprocket nut. Oil both the face of the nut and the sprocket. Red loctite, torque to 35ft lbs, back off and re torque. Then another 35*-45* of a turn. My torque wrench topped out at 250 well before the 35* mark. I ended up having to break out the impact to get it there. I stopped short of 45* because I wanted to make sure the nut locking plate still lined up with the holes in the pulley.

Red loctite the retaining bolts and torque to spec. I want to say around 105in lbs but don't hold me to that.. And the pulley is finally on!

After that it was time for the sprocket nut. Oil both the face of the nut and the sprocket. Red loctite, torque to 35ft lbs, back off and re torque. Then another 35*-45* of a turn. My torque wrench topped out at 250 well before the 35* mark. I ended up having to break out the impact to get it there. I stopped short of 45* because I wanted to make sure the nut locking plate still lined up with the holes in the pulley.

Red loctite the retaining bolts and torque to spec. I want to say around 105in lbs but don't hold me to that.. And the pulley is finally on!

Last edited by monster715; 01-17-2015 at 05:59 PM.

#164

#166

Book calls for it to be .100-.125 from the MDG, I think mine ended up around .117

I've used the removal tool to set the spacing of the race to the MDG (measuring the removal tool to make sure it is with in MOCO specs first). Works like a charm!

Awesome work! Living vicariously through this thread!

I've used the removal tool to set the spacing of the race to the MDG (measuring the removal tool to make sure it is with in MOCO specs first). Works like a charm!

Awesome work! Living vicariously through this thread!

#169

That Georges Garage pulley lock looks better than the one I got off EBay. Where are the picks of the main shaft seal install? Do you really have to pull the transmission out for that?

Are you using all HD seals or anything else?

Thanks for the pics, guess I am getting greedy!!

That picture of the transmission kept me up last night, just so you know!

Are you using all HD seals or anything else?

Thanks for the pics, guess I am getting greedy!!

That picture of the transmission kept me up last night, just so you know!

Last edited by HD Pilot; 01-17-2015 at 07:37 PM.

#170

Book calls for it to be .100-.125 from the MDG, I think mine ended up around .117

I've used the removal tool to set the spacing of the race to the MDG (measuring the removal tool to make sure it is with in MOCO specs first). Works like a charm!

Awesome work! Living vicariously through this thread!

I've used the removal tool to set the spacing of the race to the MDG (measuring the removal tool to make sure it is with in MOCO specs first). Works like a charm!

Awesome work! Living vicariously through this thread!

That Georges Garage pulley lock looks better than the one I got off EBay. Where are the picks of the main shaft seal install? Do you really have to pull the transmission out for that?

Are you using all HD seals or anything else?

Thanks for the pics, guess I am getting greedy!!

That picture of the transmission kept me up last night, just so you know!

Are you using all HD seals or anything else?

Thanks for the pics, guess I am getting greedy!!

That picture of the transmission kept me up last night, just so you know!

I'm going ton try and keep the pics coming. I'm working on a pretty slick setup for an oil pressure gauge right now too